Advanced Engineering Software with Various Functions

We sell and support software that works with existing CAD/CAM and enables an engineering flow that includes topology optimization, architected materials, etc.

As 3D printing technology has advanced, there is a growing demand for DfAM (Design for Additive Manufacturing), which involves designing with a high degree of manufacturing freedom compared to traditional processing methods in order to maximize the potential of the unique features of 3D printers. In this context, nTopology emerges as an advanced software that takes functional shapes derived from existing CAD systems, incorporates parameters defined through tools like Excel, and allows output to various formats. While nTopology boasts various features, I’d like to focus on the functionalities that are particularly noteworthy and deserve special attention.

DfAM Software nTopology Explanatory Video

About nTopology, a cutting-edge software that further expands the possibilities of 3D printers.

We have uploaded videos about our latest products, technologies, and various other information.

Please take a look at them as well.

1. Generative Deign

Generative Design refers to the concept where engineers and designers input design criteria (such as strength requirements) and artificial intelligence (AI) automatically generates designs based on those inputs.

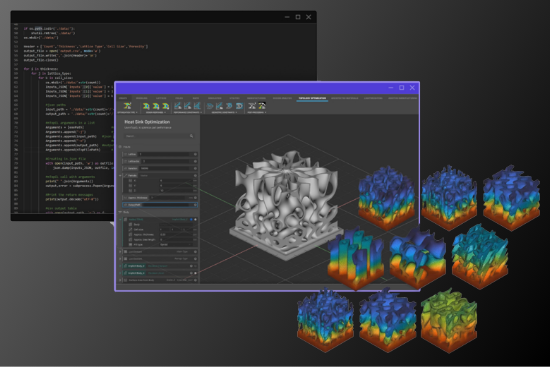

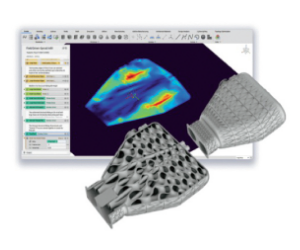

In the context of nTopology, Generative Design encompasses features such as “Architected Materials (Lattice Structures),” “Topology Optimization,” and “Field-Driven Design.

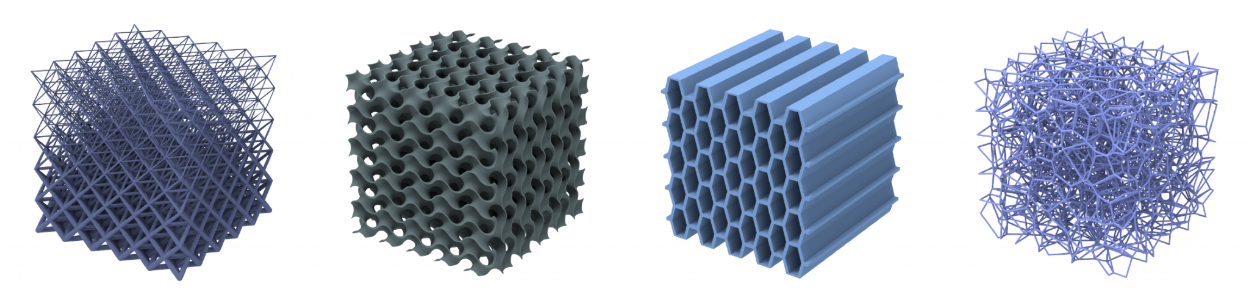

1-A.Architected Materials (Lattice Structures)

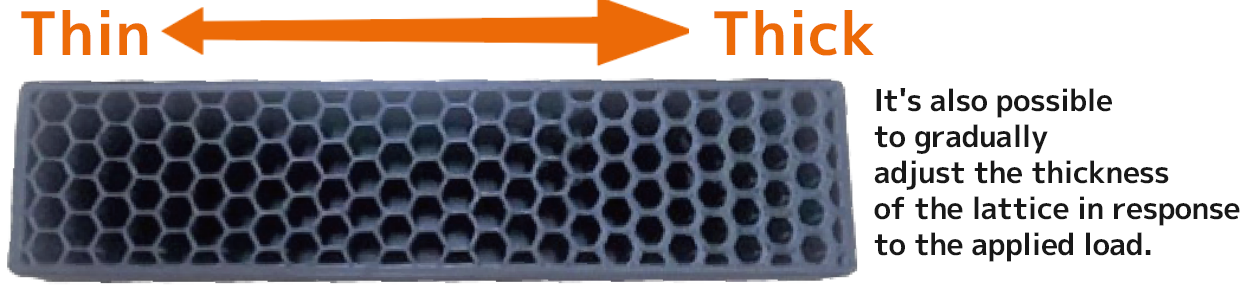

When it comes to lattice structures, nTopology allows for the instantaneous design of lattice shapes that suit specific conditions. By establishing conditions where certain areas of the structure bear loads, it becomes possible to dynamically adjust the “cell structure parameters” to match those conditions. Furthermore, it’s also feasible to enhance the fill density in particular regions.

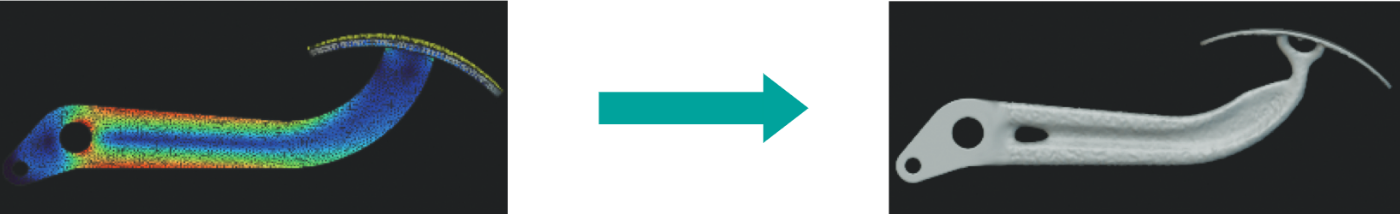

1-B.Topology Optimization (Shape Optimization)

You can achieve innovative shape designs that break away from conventional norms. By inputting conditions (such as strength) into the original product shape and automatically removing areas not subjected to loads, this design approach automatically generates shape proposals.

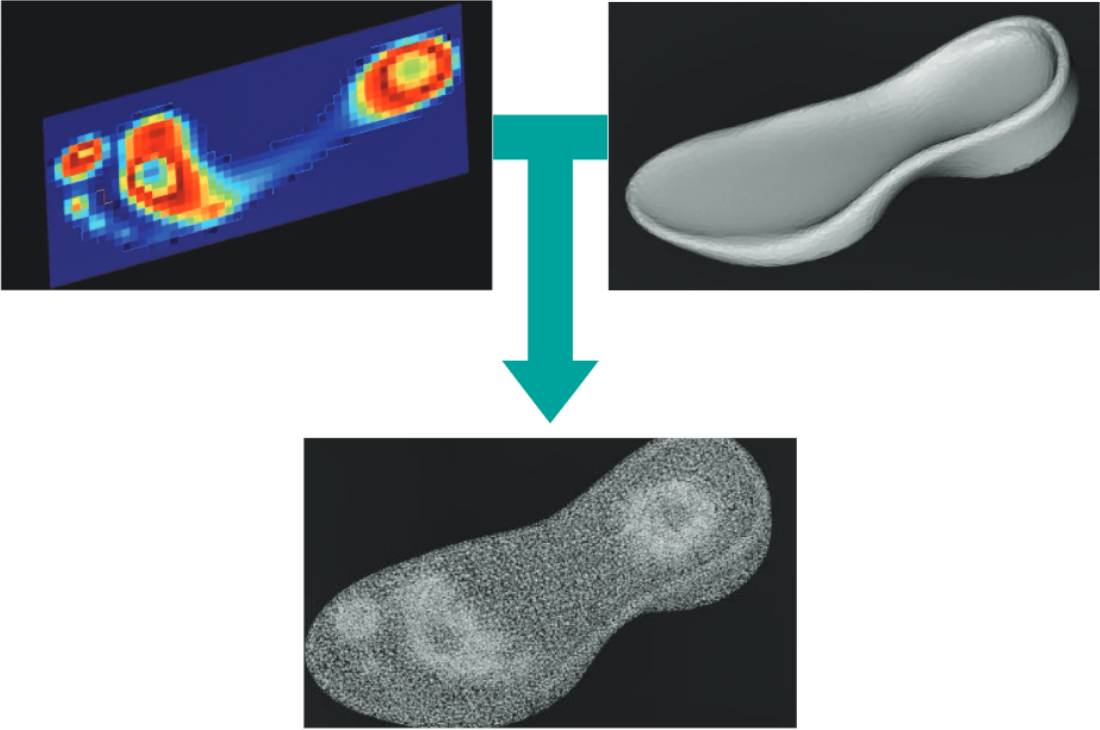

1-C.Field-Driven Design

Shape can be set by combining various data.

nTopology can combine data from various fields (CAD data, mesh data, plane data, point data, simulation results, measurement data, etc.) for designing. nTopology can design the optimum geometry based on these data.

1-D.Simulation (Analysis)

You can design by combining simulation (analysis) data with shape data. By integrating material properties and characteristics with applied loads (such as forces), it’s possible to significantly reduce the time required for design analysis conducted in various departments.

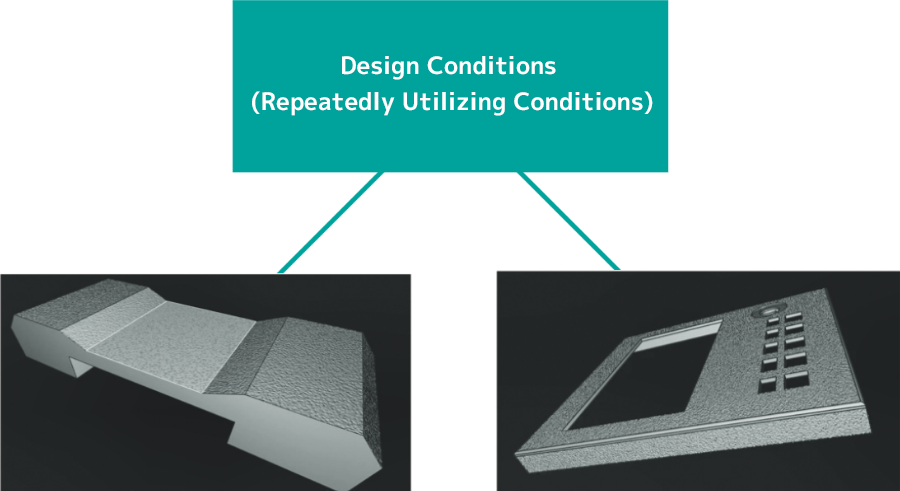

1-E.Design Automation

When designing new shapes (objects), it’s possible to repeatedly utilize conditions set in the past. Data such as lattice structure parameters, topology optimization, and field-driven design can be applied to different shapes.

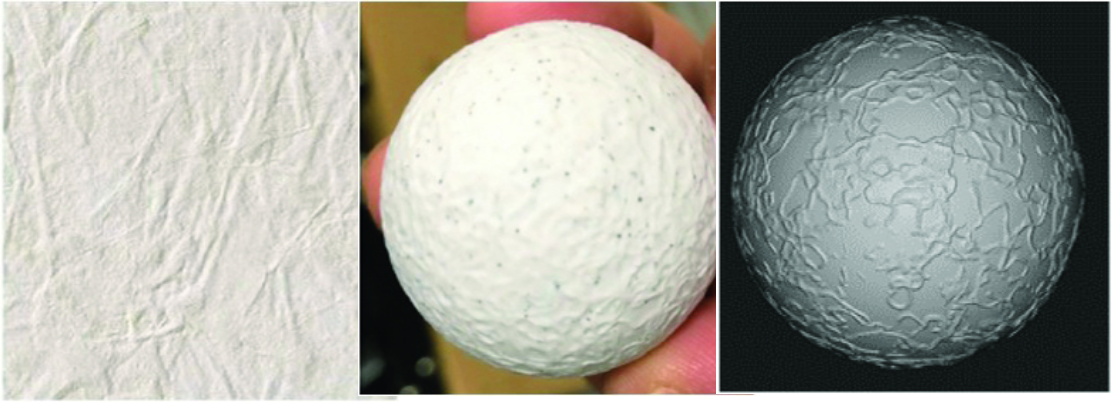

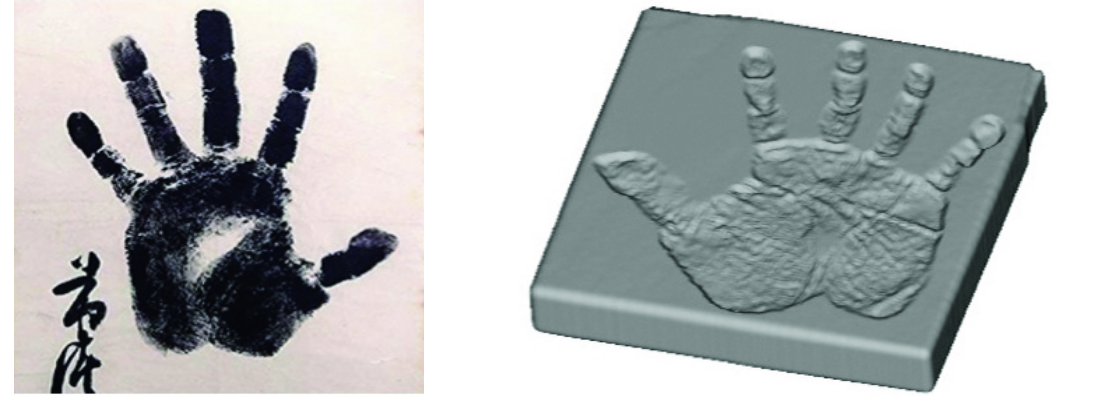

2.Digital emboss processing, Rib

It is a tool for digitizing the designer’s intentions, and can automatically convert 2D into 3D.

This tool can automatically generate emboss processing, which is a very time-consuming process with conventional CAD, thus saving a great deal of time.

Furthermore, it’s possible to reduce the visibility of layering lines, a feature of MEX 3D printers.

It’s also possible to automatically position stress-calculated boss ribs on thin walls.

Leave it to us for anything related to 3D printers!

We provide comprehensive support for your needs, from 3D printer hardware to filaments, tailored to your fabrication requirements. Additionally, we offer experienced technical support for contract and processing services, adapting flexibly to your specific requests. Feel free to contact us anytime.

03-3614-4100

03-3614-4100

To mail form

To mail form