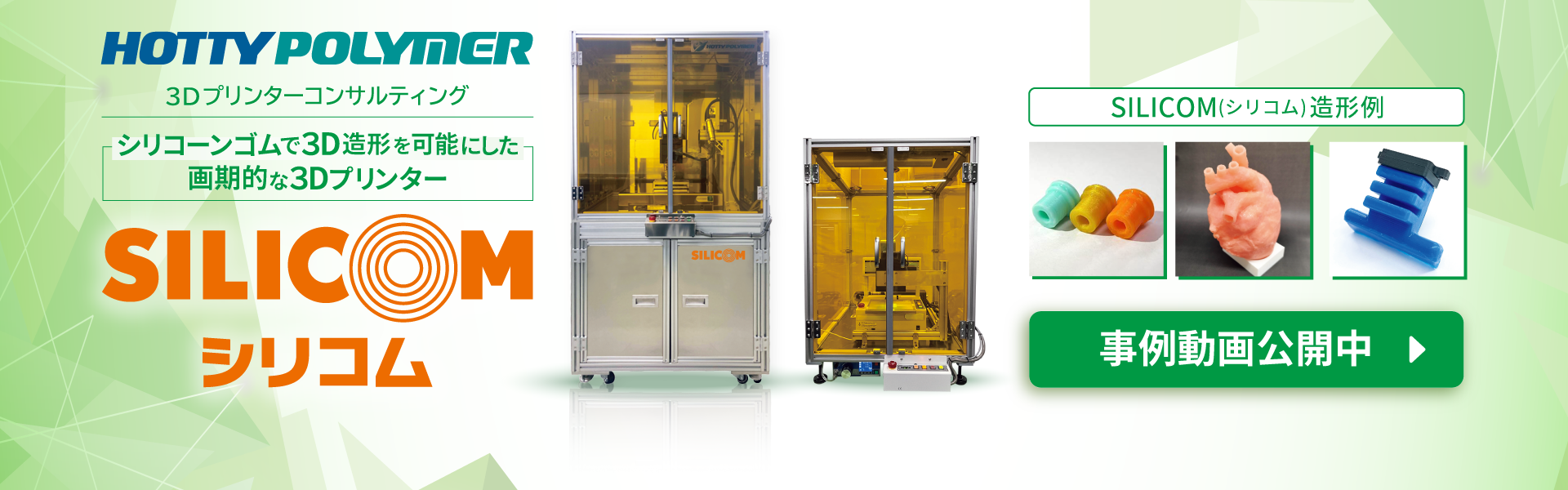

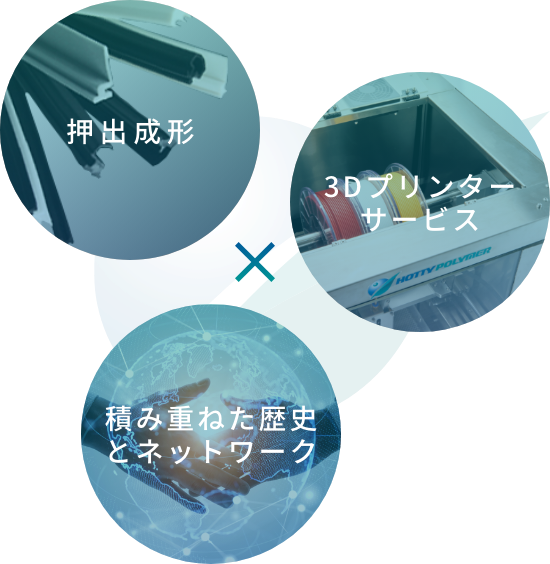

3D printer total service

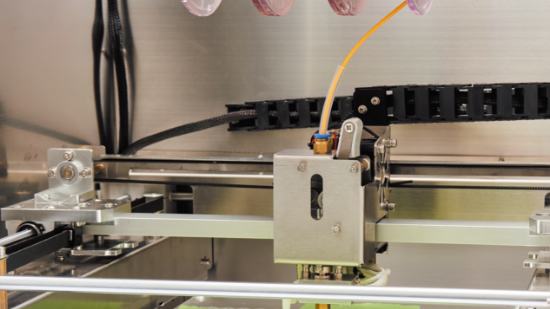

We propose solutions for the introduction of 3D printers and development and manufacturing utilizing 3D printers, such as development and sales of 3D printers, manufacturing and sales of filaments for MEX 3D printers, and 3D modeling services.

3D printer service

We provide various services related to 3D printers.

- 3D printer consulting

- Filament development, manufacturing and sales

- Sales of resin for stereolithography machines

- Development and sales of 3D printers

- Contract processing service

- DfAM software nTop

-

3D bone model

Data creation/modeling service -

3D scan

Data creation/modeling service - 3D printer showroom

- 3D printer labo

- DESIGN FACTORY

- 3D Large-Scale Contract Modeling Services

- pellet 3D printer WASP

- BambuLab low-cost, high-speed MEX 3D printer

- 3D foot scanner sales

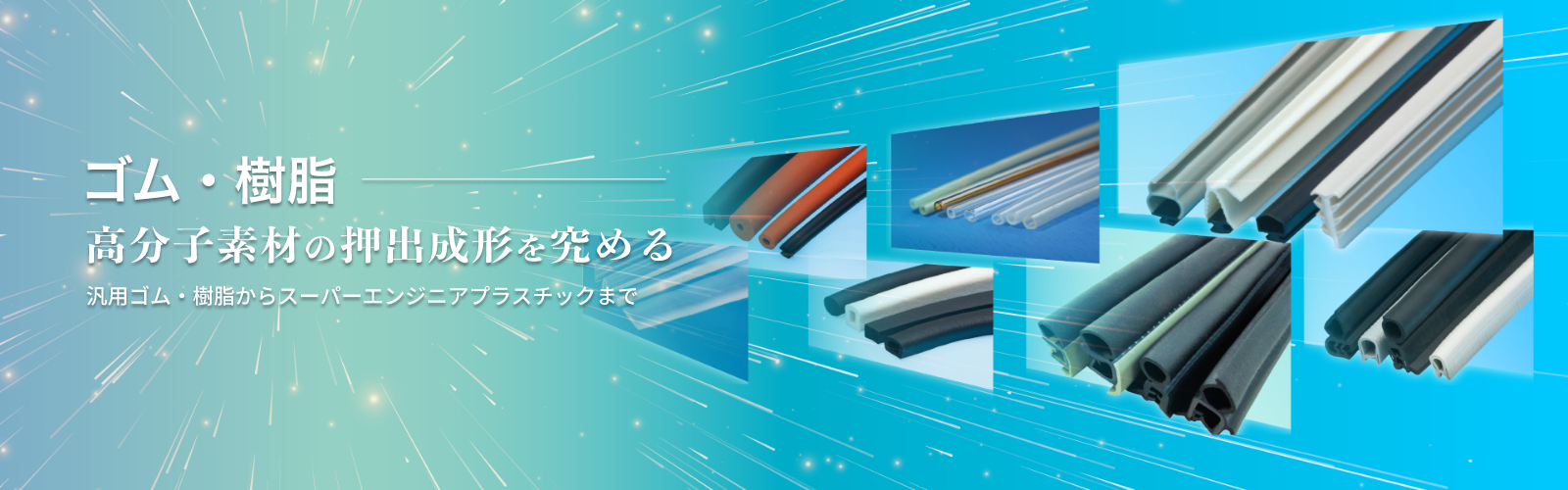

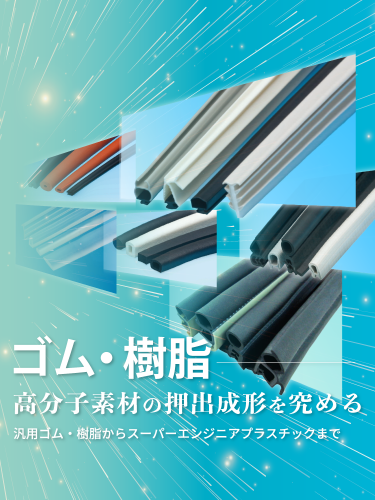

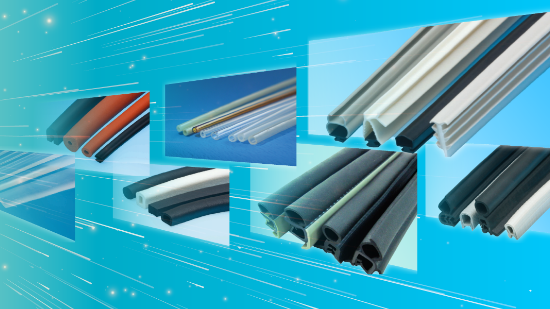

Extruded products such as rubber

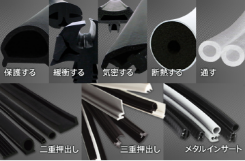

From general-purpose rubbers and resins to high-performance rubbers and super engineering plastics, as an expert in rubber and resins, we offer profile extrusion, multi-layer extrusion, and other molding methods for various materials.

Extrusion product search

Search by field

- Building materials

- Car

- Medical/Physical Chemistry

- Construction machinery/Railway vehicles

- OA / light electric

- Mechanical robot

- LED related

Search by material

- Soft material

- Resin/Engineering plastic

- Material hardness

- Heatproof temperature

- Flame retardant material

03-3614-4100

03-3614-4100

To mail form

To mail form