It is important to choose from a wide variety of resins according

to the characteristics of the modeling object and its application.

SLA 3D printers create models with liquid resin that cures with ultraviolet light.

Resins are available for various applications, including general industrial resins, rubber-like resins, ABS-like resins, and medically approved resins.

The most important factor is “resin selection,” and the finish of the modeling object will vary depending on the type of resin chosen.

There is a wide variety of resins available, so it is important to choose the one that best suits the characteristics and application of the modeling object.

Types and Applications of Resins for SLA 3D printers

Resins for general applications

-

General Industrial Resins

Black/Super clear/white/gray

A low-cost resin but allows for high-definition printing.

A standard resin with a low odor. -

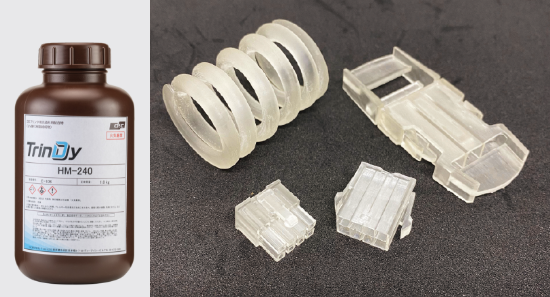

HM-240 ABS-like Resin

Transparent/Black

The combination of elastic modulus and impact resistance brings it close to the properties of ABS resin.

The low viscosity compared to competitors’ products results in fewer printing defects and more accurate printing.

Flexible Resins

-

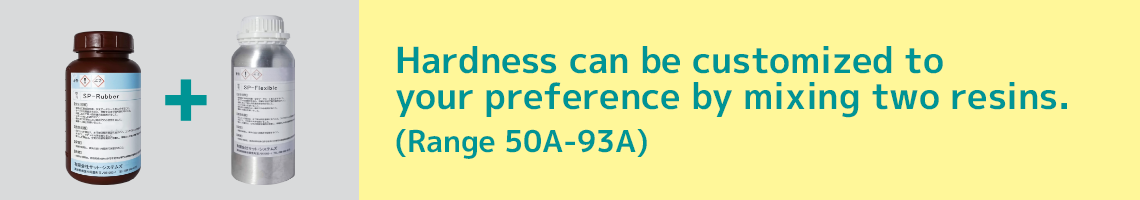

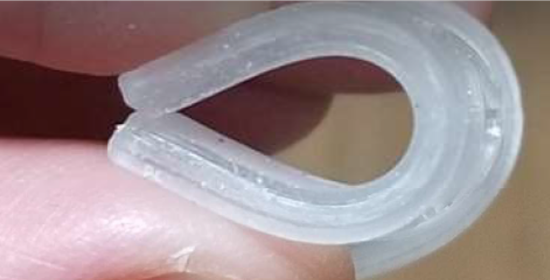

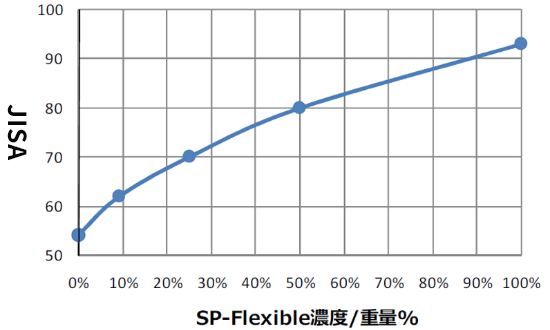

SP-Rubber (Rubber-like)

Clear

This is a resin that allows for customizable softness. By mixing it with SP-Flexible, you can achieve the desired level of hardness. Rubber Hardness: 50A.

-

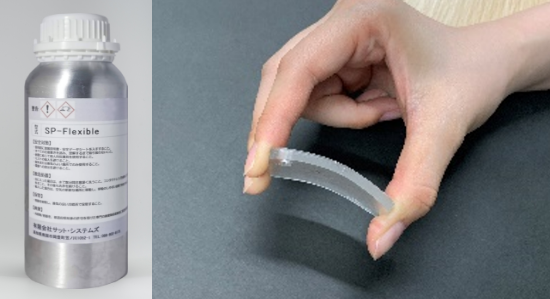

SP-Flexible (Flexible)

Clear/White/Black

This is a resin that allows for customizable softness. By mixing it with SP-Rubber, you can achieve the desired level of hardness. Rubber Hardness: 93A.

-

HS-830 Rubber-like Resin

Clear

It has a flexural modulus, high elongation and high recovery, and exhibits elastomeric properties. (Rubber hardness 50A)

It is used in cushioning jig applications where you do not want to scratch the product, and in prototypes that require softness, such as shoe insoles and midsoles.

Please contact us for a recipe (material distribution) to approach the target hardness.

Dental Resins

-

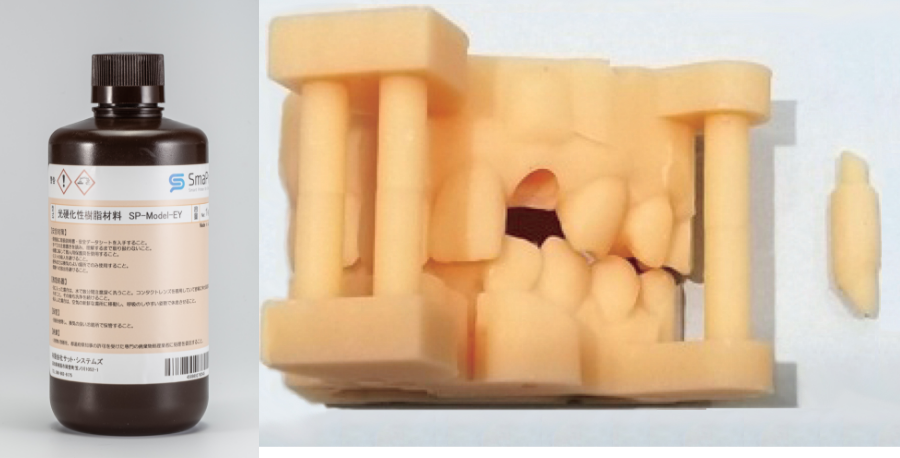

Sp-Model-EY

For modeling

It has been cost-optimized compared to conventional products and is being used as a working model derived from CAD designs and intraoral scans.

Product Name: Photocurable Resin Material SP-Model-EY

Notification Number: 39B2X10004000054

Category: Dental Materials 08 Dental Gypsum and Gypsum Products

General Medical Device Dental Resin-based Model Material -

Trindy DT-CM-220

For casting (pink)

Casting is possible with cristobalite burial material and is heat shock resistant. Further time reduction is realized. This resin is used for casting in the dental and jewelry industries and is very soot resistant.

Product Name: Trindy DT-CM-220 Cast

Notification Number: 23B1X10001C03009

Category: Dental Materials 03 Denture Base Materials

General Medical Device Dental Pattern Resin -

TrinDy DT-SG-160

For surgical (transparent yellow)

It is a biocompatible material for surgical guides. It can also undergo AC sterilization treatment.

Product Name: Trindy DT-SG-160 Surgical

Notification Number: 23B1X10001A58044

Category: Instruments 58 Orthopedic Instruments

General Medical Device Dental Implant Prosthetic Appliance

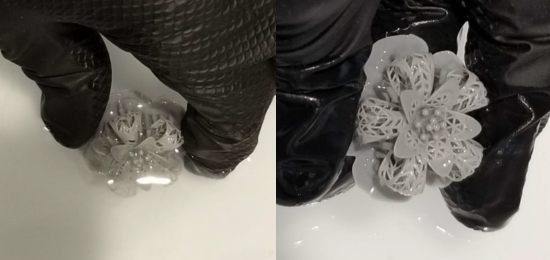

Water-washable Resins

-

SP-Wash

Black/White/Gray

・High resolution and high precision output can be faithfully reproduced.

・It is available with SmaPri under optimal conditions.

・Uncured resin clinging to the object can be washed off with water.[Note] Handling of waste liquid.

Please note that the water from washing is not to be disposed of in the sink, but rather as industrial waste. -

Can be washed with water after printing

Models printed by SLA generally need to be cleaned with IPA or other chemicals because of the excess resin on them, but with water-washable resin, models can be cleaned with water instead of IPA after printing.

What is IPA?

UV curable resin used in SLA must be washed off with IPA (organic solvent such as isopropyl alcohol or ethanol) after printing to wash off uncured resin clinging to the printed object. IPA is classified as a Class 2 organic solvent in the same framework as acetone and xylene. It is a highly toxic and flammable solvent, has a strong odor, and ventilation is essential.

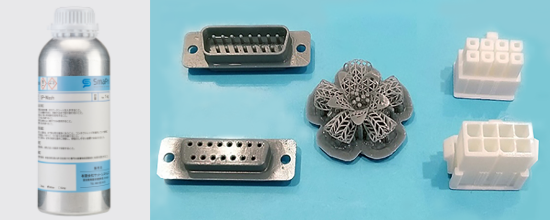

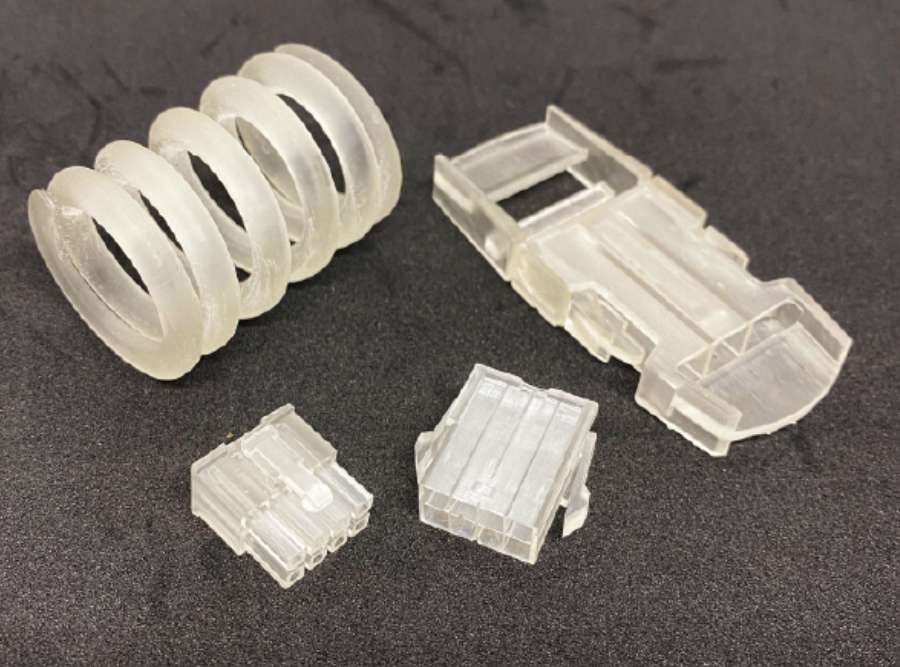

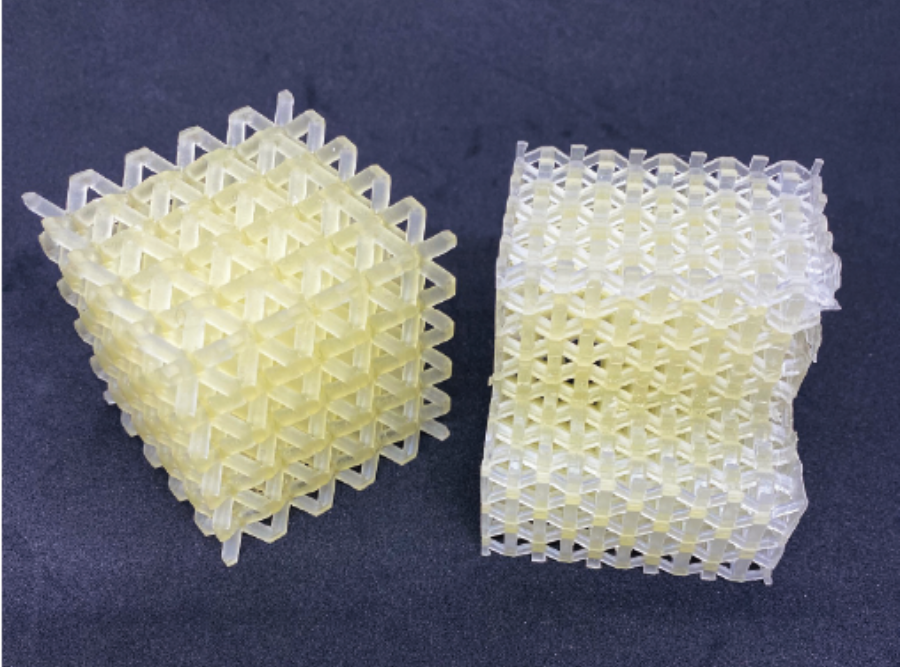

3D printing service for SLA/LCD methods

We offer contract manufacturing of various molded products using photopolymerization 3D printers. The advantage of this technology lies in its ability to create internal structures such as hollow or honeycomb patterns. This capability enables us to achieve material cost reduction and lightweight designs compared to solid machining, resulting in significant waste reduction and cost savings. Additionally, we can accommodate shapes that are otherwise difficult to produce through traditional machining processes.

-

General industrial resin

-

ABS resin

-

Rubber-like (50A)|Flexible(93A)

-

Special Resin (High Strength / Heat Resistant / Casting)

Leave it to us for anything related to 3D printers!

We provide comprehensive support for your needs, from 3D printer hardware to filaments, tailored to your fabrication requirements. Additionally, we offer experienced technical support for contract and processing services, adapting flexibly to your specific requests. Feel free to contact us anytime.

Safety Data Sheet

Safety Data Sheet 03-3614-4100

03-3614-4100

To mail form

To mail form