Cut to length

We can cut extruded products into desired sizes and deliver them to you.

Tolerances vary depending on the material and hardness, so please contact us for details.

Double-sided tape application

This process involves applying double-sided adhesive tape to extruded products.

Various double-sided tapes are available, such as Sumitomo 3M, Nitto Denko, Ebisu Kasei, etc.

Notch, Thomson die processing

Extruded products can also be processed using Notch or Thomson die processing.

Endless processing

Extruded products are cut to standard lengths and the ends are endlessly joined.

There are various methods of endless processing, and we can propose endless processing to meet your requirements.

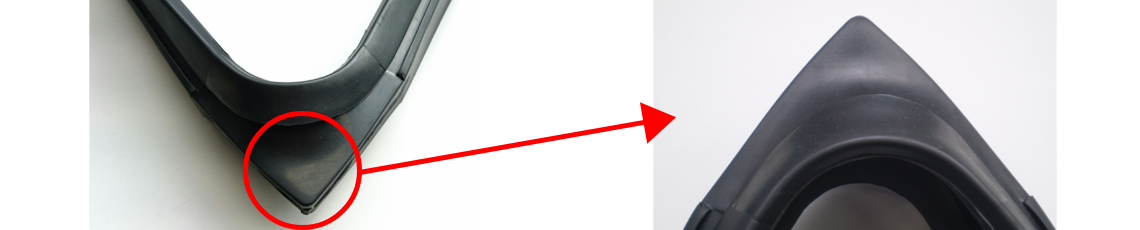

1)Vulcanized joints

This is an endless process mainly used for rubber.

It has the highest strength of all endless processing and is often used for packing around automobile doors.

The end of the product is inserted into a mold using a method similar to compression molding, and rubber is injected into the joint part and vulcanized to form a joint.

A joint mold (special compression molding mold) is required to perform vulcanization joints.

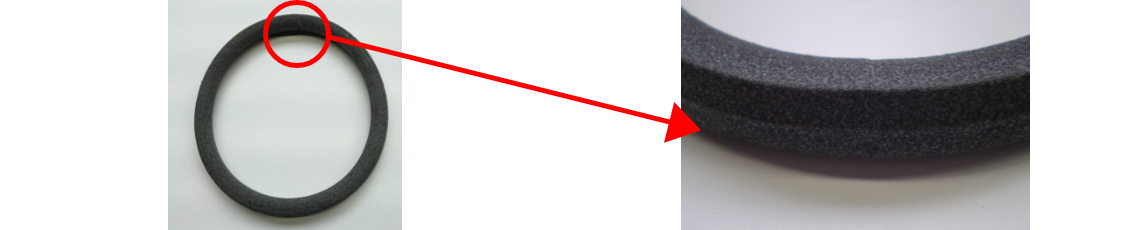

2)RTV joints

This is an endless process mainly used for silicone rubber.

RTV is applied to the edge of the product and inserted into a simple joint die, where it is thermally cross-linked to form a joint.

This process is cost-effective, but less strong than vulcanized joints.

Although the manufacturing of a mold for RTV adhesion is required for implementation, the price is lower than that of the vulcanized joint mold mentioned above.

3)Thermal welding

This is an endless process mainly used for resins.

The edges of the product are melted on a hot plate, and the melted edges are adhered to each other to weld them together.

To perform this process, it is necessary to fabricate a welding die.

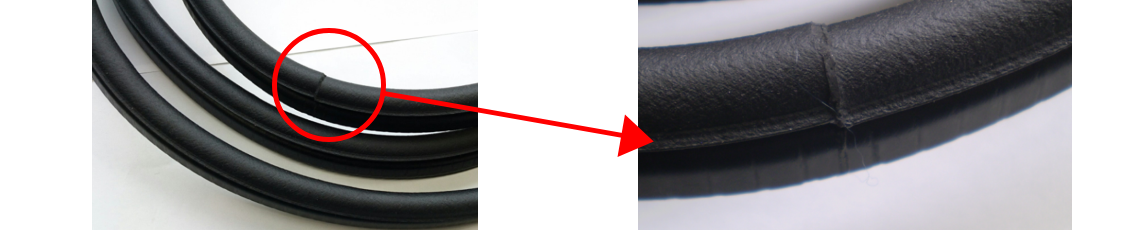

4)Adhesive processing

This is an endless process used for both rubber and resin.

Adhesive is applied to the edges of the product, and the edges are adhered to each other.

Instant adhesives are mainly used, but in the case of rubber, a rubber glue type adhesive is used if the elasticity of the bonded part is to be maintained as much as possible. Rubber glue type adhesives are used mainly in the case of CR.

Compared to other endless processing, this method does not require the fabrication of molds and requires less processing time, which reduces costs, but it is inferior in terms of strength and finish.

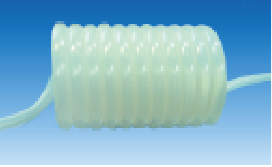

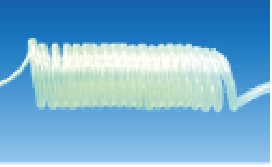

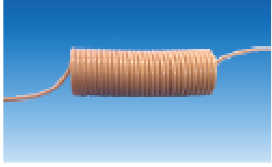

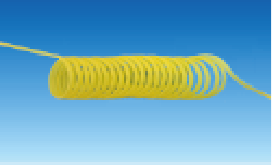

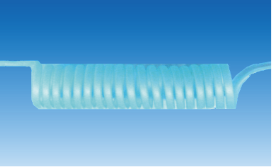

Spiral process

Spiral processing can be made to your specifications, such as coil size and winding diameter. Please feel free to contact us for more information.

-

Polyamide Spiral Tube

-

Super Viewup Spiral Tube

-

PEEK Spiral Tube

-

Statore Spiral Tube

-

Super Viewup Spiral Tube

-

Luminous Spiral Tube

-

Super Viewup Spiral Tube

-

Polyamide Tape Coil

-

Polyamide Tape Coil

-

Luminous Tape Coil

-

Statore Tape Coil

-

Statore Tape Coil

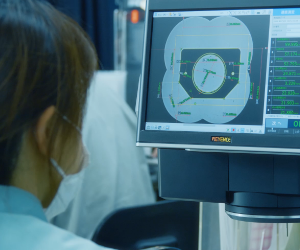

We are your source for extrusion molding!

Over many years of research and manufacturing, our high-performance rubber extrusion products and high-performance resin extrusion products have been highly evaluated for their high quality and reliability in a wide range of fields such as construction materials and automotive applications.

Based on our rich experience and achievements cultivated over the years, we are able to make optimal proposals tailored to our customers’ needs, which only HOTTY Polymer can provide.

03-3614-4100

03-3614-4100

To mail form

To mail form