Install a 3D printer in your company, and you can propose solutions to problems.

As polymer solution experts, we offer a comprehensive range of services, starting from proposing prototyping using 3D printers to providing solutions for mass production through extrusion molding, compression molding, and injection molding. While the following is just a small sampling, we would like to showcase some examples of these cases here.

Case Study – Example 1: Reduction of Mass Production Costs

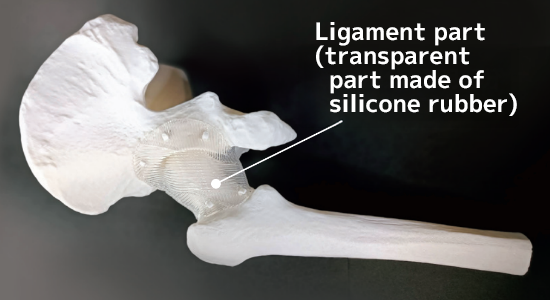

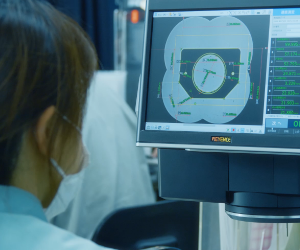

We received a project involving the consideration of a ligament surgery training model.

The conventional imported models were discarded after training sessions, raising concerns about cost-effectiveness.

We proposed a solution by making the ligament section (transparent part made of silicone rubber) detachable and utilizing 3D printing for the entire model. This approach resulted in a significant cost reduction of approximately 50%.

Furthermore, the compact size of the model, compared to the previous version, made it more portable, allowing distribution to the entire sales team for easier transportation.

Material : PLA + Silicone Rubber

Benefits: Cost reduction of approximately 50%.

Transition from single-use to detachable design,

reducing waste (environmental contribution).

Case Study – Example 2: Reduction of Prototyping and Mass Production Costs (Compression Molding)

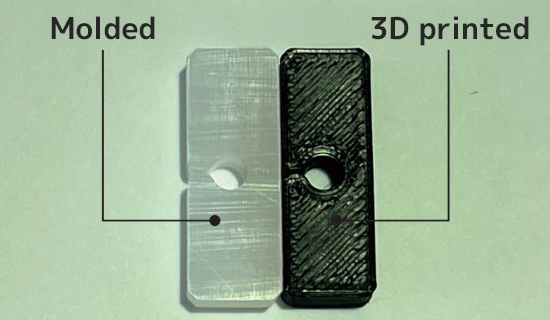

We received a consultation from a machinery-related trading company for parts for home appliances.

The client consulted us about rubber grommets, but since the development project was urgent, we used HP filament (super flexible type) to adjust the hardness by filling ratio before manufacturing the mold, and created 3 sizes of products with 1mm difference using a 3D printer.

After selecting the size with the best fit among the three, we fabricated a compression molding die at our overseas partner factory and were able to shorten the prototype delivery time, reduce the cost of modifications, and reduce the cost of mass production.

Material : 3D print ⇒HPF Super flexible type

Infill 50% (JISA50assumed)

Mass production ⇒Silicone Rubber 50°(JISA)

Benefits: Cost reduction in prototype mold production without actually creating prototype molds.

Achieved a 1-day 3D prototype printing schedule, resulting in accelerated development timelines.

Reduction in mass production costs through outsourcing to overseas manufacturers.

Case Study – Example 3: Reduction of prototype costs (extrusion moulding)

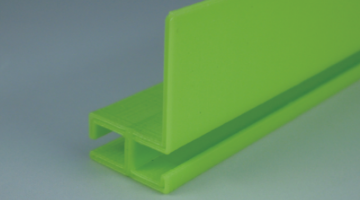

The project was for a corner cover for a door component.

In the past, the extrusion mould would have to be made, tested and then modified or the mould would have to be re-made depending on the condition.

By creating a prototype with a 3D printer and evaluating it before creating the extrusion mould, we were able to reduce costs through trial and error.

Material: PVC

Initial Investment (Extrusion mould fee): ¥650,000

Prototype creation with 3D printers.

Prototype creation with 3D printers.

Material: PLA

Prototype cost: ¥ 10,000-.

Longer models of about 3 metres are also possible.

Longer models of about 3 metres are also possible.

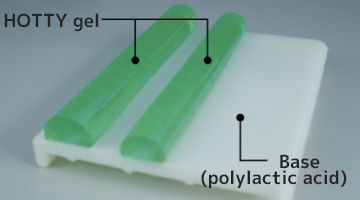

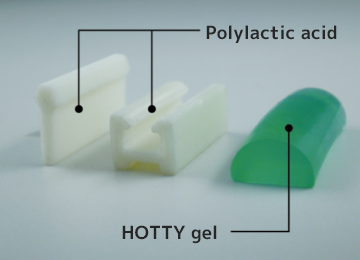

We received a project as a set-up material for bathroom parts.

We proposed a shape that was easy to extrude and mould, and we made a hard part and stuck our gel on it to make a ‘gel gasket’, and after checking the condition of the gasket, we proposed to mould it.

Material: PP + HOTTY gel (gel gasket)

Initial investment (extrusion mould cost): ¥450,000-

3D printer creates a hard part and sticks the gel on it.

3D printer creates a hard part and sticks the gel on it.

Material: polylactic acid (PLA) + HOTTY gel.

Prototype cost: ¥75,000-

Case study – Example 5: Reduction of prototype costs (extrusion moulding)

We received a project as a waterproofing material for bathroom components.

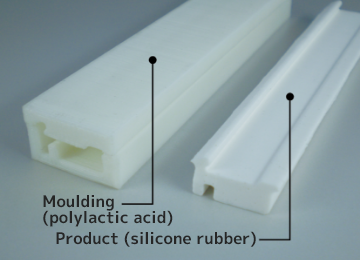

We proposed a shape that was easy to extrude, made a mould frame out of polylactic acid (PLA) and injected room temperature curing silicone. We made an extrusion sample of about 150 mm in length and proposed corner-following properties.

Material: EPDM foam

Initial investment (extrusion mould cost): ¥60,000-

3D printer moulds and moulds room temperature curing silicone

3D printer moulds and moulds room temperature curing silicone

Material: polylactic acid (PLA) + silicone rubber.

Prototype cost: ¥10,000-

Case study – Example 6: Reduction of mass production costs (compression moulding)

We received a proposal for an airtight piece for a building component.

As the lot size was small and it was difficult to amortise the investment in the mould, we proposed a simple mould made from polylactic acid (PLA), filled with room temperature cured silicone rubber and cured.

Material: silicone rubber

Initial investment (press die cost): ¥150,000-.

Product cost: ¥1,000- (lot of 5).

3D printer moulds and moulds room temperature curing silicone

3D printer moulds and moulds room temperature curing silicone

Material: Mould ⇒ polylactic acid (PLA), Product ⇒ silicone rubber

Production costs: mould => ¥15,000-, product => ¥1,000- (lot 5 pieces)”

Leave it to us for anything related to rubber amd resin!

“Over many years of research and manufacturing, our high-performance rubber extrusion products and high-performance resin extrusion products have earned a reputation for high quality and high reliability in a wide range of fields, including construction materials and automotive applications.

Based on the wealth of experience and achievements we have built up over the years, we are able to make optimal proposals tailored to our customers’ needs, which only HOTTY POLYMER can provide.”

03-3614-4100

03-3614-4100

To mail form

To mail form