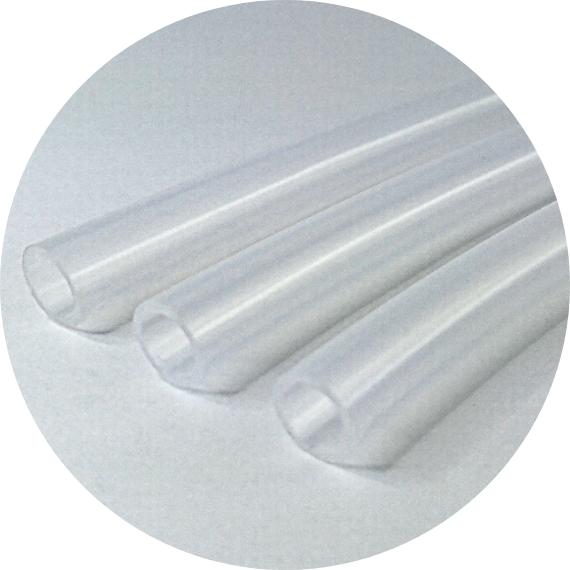

Non tacky silicone tube

Fluorine gas surface treated products with improved tackiness of silicone rubber

Silicone rubber extrusion products with improved tackiness modified

by an innovative fluorine gas surface treatment method.

Silicone rubber is a material that is easily charged and has a unique tackiness, which makes it easy for dust and dirt to adhere to it and difficult to remove the dust and dirt.

Non-tacky silicone tubing is a proprietary product that chemically modifies the surface of silicone rubber by bringing it into contact with fluorine gas (vapor p hase treatment).

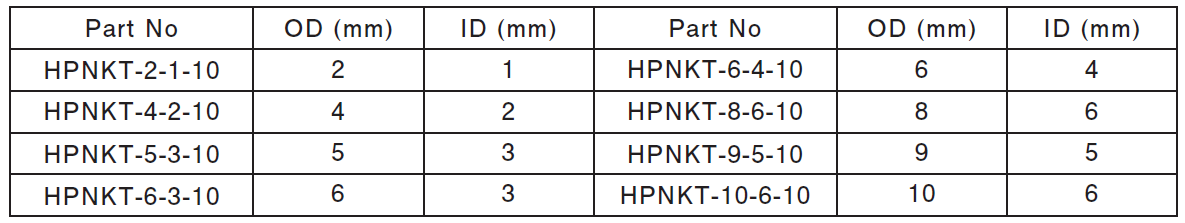

B ecause the surface i s chemically modified rather than being l ayered coated like DLC (hard carbon film) or PTFE (fluoroplastic) coated products, it is more uniform, durable, flexible, and cost effective than s urface coated p roducts. Even after fluorine gas treatment, the chemical resistance, heat resistance, and flexibility are equivalent to those of silicone rubber. Tubes are available in the following sizes with a hardness of 55° and can be purchased in 10-meter increments.

Features

Tack resistance

Reduces adhesion of dust and dirt on

the surface,

which is characteristic of silicone rubber.

Durability

Superior durability compared to

coatings due to surface modification.

Adhesion resistance

Reduces adhesion to mating

materials even in special

environments.

Uniformity

Unlike coatings, there is no

increase in hardness, and uneven

coating can be reduced.

Variety of product lines

Eight different sizes are

available. Custom-made

sizes are also available.

Chemical resistance

Chemical and ozone

resistance can be improved.

Application

Tubes, packings, oil seals, gaskets for products related to medical equipment, physical and chemical equipment, automobiles, electronics, analytical equipment, semiconductors, etc.

03-3614-4100

03-3614-4100

To mail form

To mail form