Company Profile

| Company Name | Hotty Polymer Co., Ltd. |

|---|---|

| Head Office | 4-43-8 Higashimukojima, Sumida-ku, Tokyo 131-0032 Access Map |

| Phone | 03-3614-4100 (Main) |

| FAX | 03-3614-4162 |

|

Kuki Plant (No. 1)

Location

Phone FAX |

1-8 Kiyoku Industrial Park, Kuki-shi, Saitama 346-0035 Access Map

0480-21-5645 (Main) 0480-23-5663 |

| Kuki Plant (No. 2) Location | 2-1 Kiyoku Industrial Park, Kuki-shi, Saitama 346-0035 |

|

Kyoto Sales Office

Location

Phone FAX |

FIS Building 2F, 403 Shimomaruyacho, 2-chome, Kawaramachi-dori Nijo-sagaru, Nakagyo-ku, Kyoto-shi, Kyoto 604-8006 Access Map

075-555-3247 075-256-8754 |

|

3D Printer

Open Lab Keio University Central Testing Laboratory Location |

Room 217, Building No. 36, 3-14-1 Hiyoshi, Kohoku-ku, Yokohama-shi, Kanagawa 223-8522 Access Map |

| Establishment | March 23, 1951 |

| Business Activities |

Manufacturing and sales of rubber and plastic products (Foam products, multicolor co-extruded products, metal insert products, joint press processing, high-performance transport rollers, molded products)

Development and sales of 3D printers, and development, manufacturing, and sales of filaments for 3D printers Contract-based 3D modeling processing services |

| Capital | 20 million yen |

| Number of Employees | 105

Group Total 154 (As of August 2024) |

|

Head Office

Site Area

Building Area |

1,333 m²

670 m² |

|

Kuki Plant (No. 1)

Site Area

Building Area |

3,050 m²

2,865 m² |

|

Kuki Plant (No. 2)

Site Area

Building Area |

3,001 m²

1,206 m² |

| Fiscal Year-End | March 31 |

| Main Banks |

MUFG Bank, Mukojima Branch

Sumitomo Mitsui Banking Corporation, Asakusa Branch Mizuho Bank, Oshiage Branch Asahi Shinkin Bank, Higashi-Mukojima Branch Shoko Chukin Bank, Head Office Japan Finance Corporation |

| Affiliations |

Japan 3D Printing Industrial Technology Association

Manufacturers’ Association of Building Gaskets Japan Rubber Manufacturers Association Society of Rubber Science and Technology, Japan Bokuto-Rubber Industry Association TGS (Tobu Industrial Rubber Products Wholesalers Association) Kuki City Kiyoku Industrial Park Council Tokyo Chamber of Commerce and Industry Tobu Rubber Health Insurance Society |

| Product Lineup |

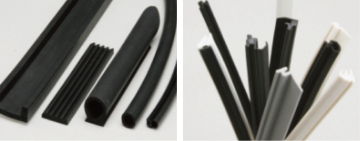

(1) High-performance rubber extrusion and compression products

NR, SBR, CR, NBR, EPDM, Q, FKM, and others (2) High-performance resin extrusion and injection products TPE, PVC, PP, PE, PS, ABS, PC, super engineering plastics, plant-based plastics, and others (3) 3D printers, filaments, and contract-based printing services MEX, SLA, LCD, and LAM-type 3D printers, as well as MEX-type 3D printer filaments |

| Certifications |

ISO 9001:2015 (JMAQA-448)

ISO 14001:2015 (JMAQA-E480) (Kuki Plants only) |

Head Office

Kuki Plant No.1

Kuki Plant No. 2 Plant No. 2 (New Resin Plant Building)

Rubber Extrusion Products Resin Extrusion Products

Facilities

| Rubber Manufacturing Equipment | Rubber Continuous Vulcanization Lines : 6 lines Extruders 9 units Kneaders : 1 unit Open Roll Mills : 4 units |

|---|---|

| Resin Manufacturing Equipment | Resin Production Lines : 13 lines Extruders : 30 units |

| 3D Printer Equipment | MEX-Type 3D Printers : 33 units LAM-Type 3D Printers : 6 units SLA-Type 3D Printers : 1 unit MSLA-Type 3D Printers : 1 unit DLP-Type 3D Printers : 1 unit LCD-Type 3D Printers : 3 units PolyJet-Type 3D Printers : 1 unit 3D Scanners : 2 units |

Rubber Extrusion Line

Resin Extrusion Line

Related Group Subsidiary Nakano Manufacturing Co., Ltd.

| Company Name | Nakano Manufacturing Co., Ltd. |

|---|---|

| Location | Head Office

3-30-6 Hosoda, Katsushika-ku, Tokyo 124-0021 Nagasaki Plant 57-28 Hattandago, Higashisonogi-cho, Higashisonogi-gun, Nagasaki 859-3922 Inside Higashisonogi Green Techno Park |

| Established | November 1987 |

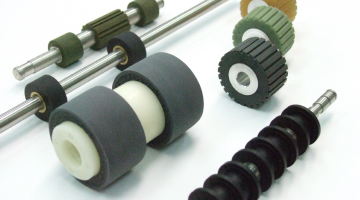

| Business Activities | Manufacturing and sales of industrial rubber products

Design, manufacturing, and sales of rubber rollers and rubber belts Design, manufacturing, and sales of ceramic rollers (High-performance transport rollers and the rubber-plastic cross-linked composite material “Radicalock”) |

| Capital | 10 million yen |

| Website | http://www.nakasei.co.jp/index.shtml |

Nagasaki Plant (Exterior)

High-Performance Transport Rollers

Rubber-Plastic Cross-Linked Composite Material “Radicalock”

03-3614-4100

03-3614-4100

To mail form

To mail form