Extrusion Molding Product Search

Search by Category

- Building materials

(housing equipment) - Automotives

- Medical/Physical

Science - Construction Machinery・

Railway vehicles - OA/Electronics

- Mechanical Robotics

- LED related

Search by Materials

Search by List

We will propose the best materials and shapes to meet your needs.

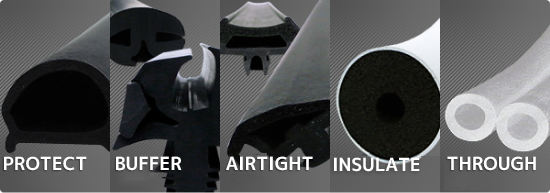

Watertightness, airtightness, heat insulation, anti-vibration, soundproofing, design, etc.

We provide high-functional parts that take advantage of the characteristics of rubber and resin extrusion products.

Hotty Polymer has handled and processed a wide variety of raw materials such as rubber and silicone over many years of research and manufacturing.

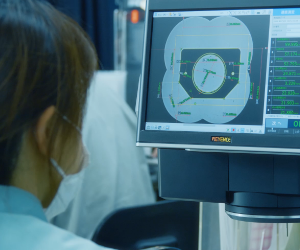

From the delicate compounding of raw materials to the compounding process and mold making that combines the latest technology with traditional craftsmanship, we have created and proposed a variety of extruded products that meet the needs of the times.

The demand for products changes with the times. We have continued to make proposals in line with the changes of the times and have continued to produce high quality products.

We believe that the best way to raise the level of our products is to provide our customers with the most advanced materials using the most advanced technology.

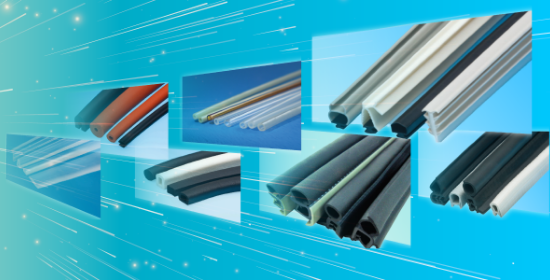

Extrusion Molding Products

The basics of extrusion molding are “What material to use? and “What shape of mold do we make?

We propose a variety of materials according to customers’ requests, design molds, and manufacture products.

Hotty Polymer has been independently researching extrusion molding technology and has achieved diversification of cross-sectional structures and high-precision processing.

Our new materials have been used in various fields, such as weather strips and glass run channels in the automotive industry, and various gaskets and joint materials in the construction industry.

In addition, extruded products are streamlining, simplifying, and enhancing the functionality of products in fields where only liquid materials could be applied in the past.

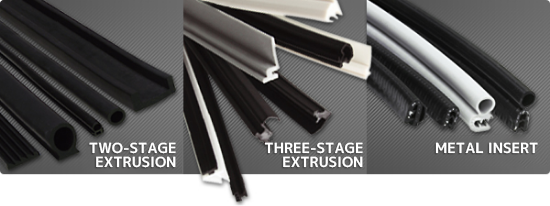

Core Extrusion Technology

Profile extrusion

By extruding materials of different hardness simultaneously and forming them into various shapes, we create a variety of products that combine both assembly and cushioning characteristics.

Cutting-edge materials with cutting-edge technology

We deal in engineering plastics and super engineering plastics, but the technological progress of resins is rapid, and super engineering plastics will soon become general-purpose plastics.

However, we believe that the best way to improve the quality of our products is to provide our customers with the most advanced materials using the most advanced technology. We are proud of this as our quality policy itself.

We are your source for extrusion molding!

Over many years of research and manufacturing, our high-performance rubber extrusion products and high-performance resin extrusion products have been highly evaluated for their high quality and reliability in a wide range of fields such as construction materials and automotive applications.

Based on our rich experience and achievements cultivated over the years, we are able to make optimal proposals tailored to our customers’ needs, which only Hotty Polymer can provide.

03-3614-4100

03-3614-4100

To mail form

To mail form