HP Filament® (Super Flexible Type) (Flexible 75A Type)

Soft filament for general-purpose 3D printers ※Only usable with direct extruder method.

This flexible filament can be used in most MEX 3D printers.

HP filament is a very flexible filament produced by our compound technology.

It has the core and is rigid when it is the filament form, and does not extend in the vertical direction during modeling. Thereby, flexible and high precise 3D models can be produced stably by general FDM mechanism 3D printers in the market.

Stabler modeling is possible by using our Sube-up Tube for 3D Printer Filament-supply.

It can be colored. Please consult us.

Reproduce the fine details

Very flexible, Easily back to original shape

Features

Flexibility

Very flexible models can be produced.

Preciseness

Precise 3D models can be

produced.

Stabler modeling is possible by using our Sube-up Tube for 3D Printer Filament-supply.

Functionality

It can be used as supporting

materials by machine settings.

Colorability

It can be colored.

Please consult us.

Applications

Prototype parts, interior products, wearable products, miscellaneous goods, outdoor equipment, sporting goods, etc.

※Quality requirements vary depending on the conditions of use, so detailed discussions are required before adopting the product.

Recommended printing conditions

- Extruder temperature : 200 – 240˚C

- Recommended print speed : 20 mm / sec or less

The recommended print speed varies depending on the model shape, the state of the nozzle, etc.

If clogging occurs, please slow the speed to 10 mm / sec etc. You can make the precise model at slower speed. - Recommended print pitch: 0.2 or less

※The printing condition varies according to the 3D printers.

※This filament can be used with the 3D printers that can print with layer height pitches 0.2 or less, such as Rep-

Rap type 3D printers, MakerBot Replicator series and compatible machines, etc.

※MakerBot Replicator and MakerBot compatible 3D printers are recommended.

MakerBot : Replicator 2, FLASHFORGE : Finder, QIDI TECHNOLOGY : X-one, QD3DA4-01, Aurora 3D Printer :

Z-603S (Molding test finished with above recommended condition)

Before use

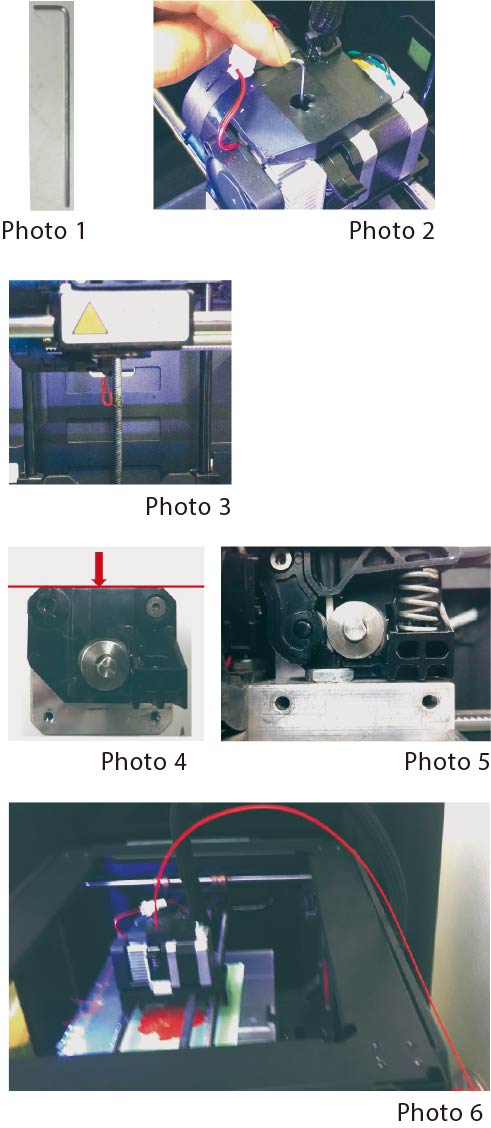

- Please remove filament material left in the nozzle with 1.7 – 1.0 Φ metal stick (cf. Photograph 1 and 2)

- If the filament gets caught in the filament guide tube, remove the guide tube.

- After cleaning the head, the nozzles of the extruder feeding guide may cause clogging because filaments cannot be sent straight ahead.

Please check if the extruder head mounted horizontally (cf. Photo 4).

In the case of flexible filaments, deviation from the drive gear affects stable filament delivery more than hard filaments (cf. Photo 5) - If filaments cannot be supplied well, please slack the filament as shown in photo 6.

5.In the case of flexible filament,the gap between the nozzle and build plate should be set bigger than hard

Other handling information

※Due to its high flexibility, if the model is crushed strongly, it may tear at the point where stress is concentrated due to the structure of the laminated model. In that case, it can be glued with general instant glue or adhesive, Aron Alpha (Toagosei) or Super X (Cemedine).

※To prevent deterioration of quality, store the filament in a zippered bag and avoid direct sunlight, high temperatures and humidity.

※Warping can be further suppressed by using build tape specifically designed for HP filament (super flexible type) for 3D printers when modeling.

Introducing our online shopping sites

You can also purchase this product on our EC site (mail order).

※You can also purchase it by contacting us directly.

■Handling EC site

・Purchase on the “MonotaRO” page

・Purchase on the “AXEL (AS ONE)” page

・Purchase on the “Orange Book.com (TRUSCO Nakayama)” page

・Purchase on the “Amazon page”

・Purchase on the “Hakudo Net Services” page

![]()

![]()

03-3614-4100

03-3614-4100

To mail form

To mail form