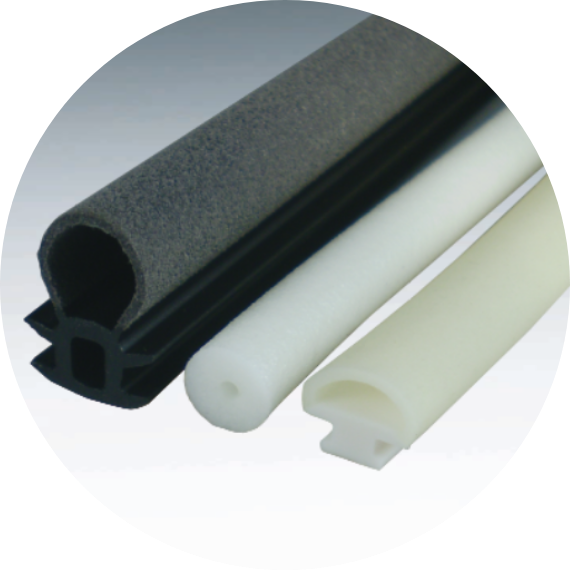

HP Foam

Achieves the same performance as EP Foam!

“HP Foam” is an epoch-making product made by foaming resin with our unique blending technology.

“HP Foam” has excellent compression set in general environment. In addition, since elastomers are originally light with low specific gravity, it is possible to reduce the weight of the product by further foaming. In addition, its high volume resistance makes it ideal for electrical insulation applications. In addition, it can be colored, which is difficult to do with general industrial rubber, and atypical extrusion is also possible. It is possible to improve the adhesion resistance by “HP Foam dedicated anti-stick treatment”.

Feature

High resiliency

Excellent compression set at room temperature,

It exhibits similar performance to EP.

Environmental Friendliness

Compared to rubber, carbon dioxide during manufacturing

Low emissions and environmentally friendly.

Colorability

Because it is made of resin compared to rubber, which is difficult to color,

Coloring is possible (negotiable).

Economy

Because the manufacturing method is different from that of rubber Foam,

It is possible to reduce production costs.

Lighter weight

By foaming elastomers with low specific gravity

Further weight reduction is possible.

Low water absorption

Low water absorption, as a water-stopping packing

Yes, it can be used.

Use

Gaskets, packings, sealing materials, sound absorbing materials, heat insulating materials, etc. for automobiles, civil engineering, construction, and various precision equipment.

It has a wide range of applications and a wide variety of applications. We will consult with you about the color, so please feel free to contact us.

Water Absorption Test

Test method: Room temperature ×24h (JIS A 5750)

You can see that the water absorption rate of HP Foam is very good. This is followed by our EP Foam (sofler), our EP Foam (special formulation), and EP Foam (general-purpose) in that order.

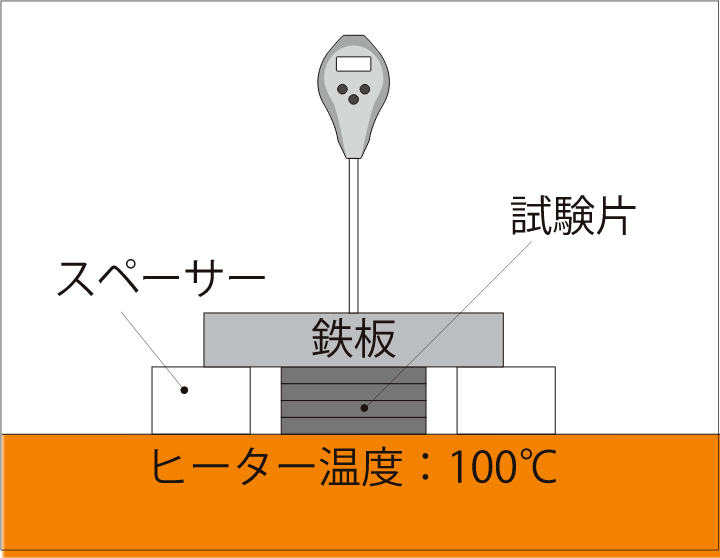

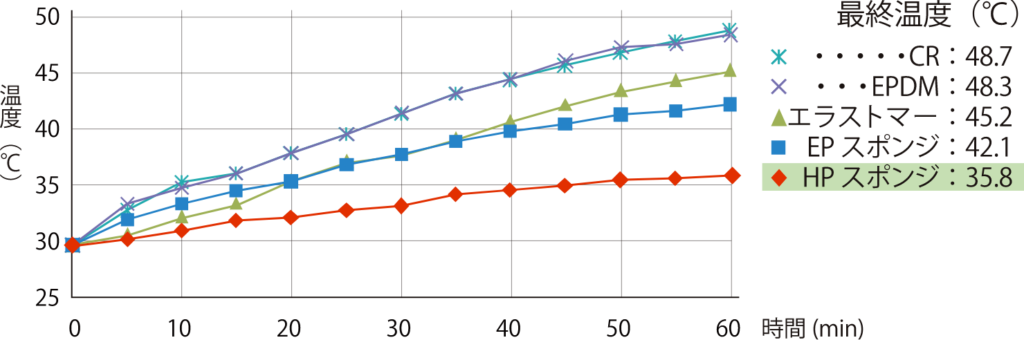

Thermal Insulation Tests

Test status: A test piece (various elastomers) with a thickness of about 3 ~ 4 mm is stacked to 20 mm, and an iron plate is placed on the test piece.

The temperature transmitted to the steel plate was measured when the temperature from the bottom was set to 100°C.

Test result: There is no difference at the beginning of the measurement, but there is a difference in temperature with the passage of time.

As you can see from the temperature at the 60-minute point, the characteristics of the HP Foam appear.

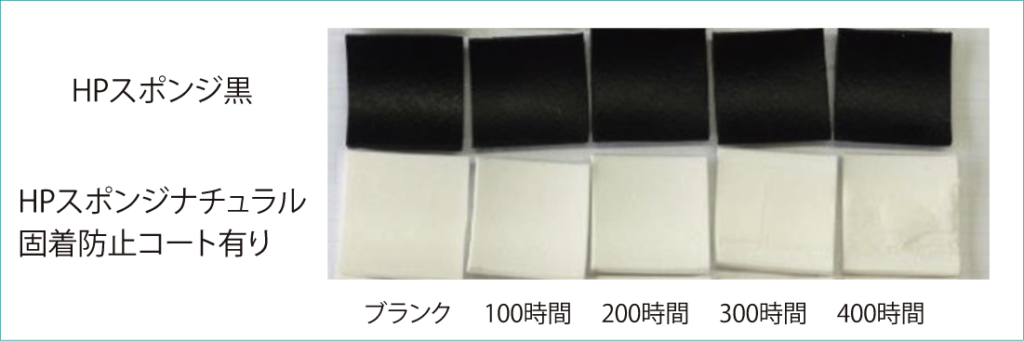

Weathering Tests

Test method: (JIS A 5750)

Test conditions

Equipment: Super Accelerated Weathering Tester Eye Super

UV Tester SUV-W151 (Iwasaki Electric)

Conditions: Black Panel Temperature 63°C, Humidity 70%, Rain

Test Results: This test equipment is the result of 400 hours of metal weather testing.

This test is more than 3~5 times more effective than the Sunshine Weather test, so there is no yellowing and it is a very effective result.

From this result, it is considered that there is no problem in places where changes in appearance are a concern, but depending on the application, such as the operating temperature and environment, it may differ from the test result, so please consult with us when using it.

03-3614-4100

03-3614-4100

To mail form

To mail form