Non-tacky silicone trim®

Improved tackiness and adhesion resistance with fluorine gas treatment One-touch easy & covenience silicone gasket

Silicone Trim® is modified by an innovative fluorine gas surface

treatment method to improve tackiness and sliding properties.

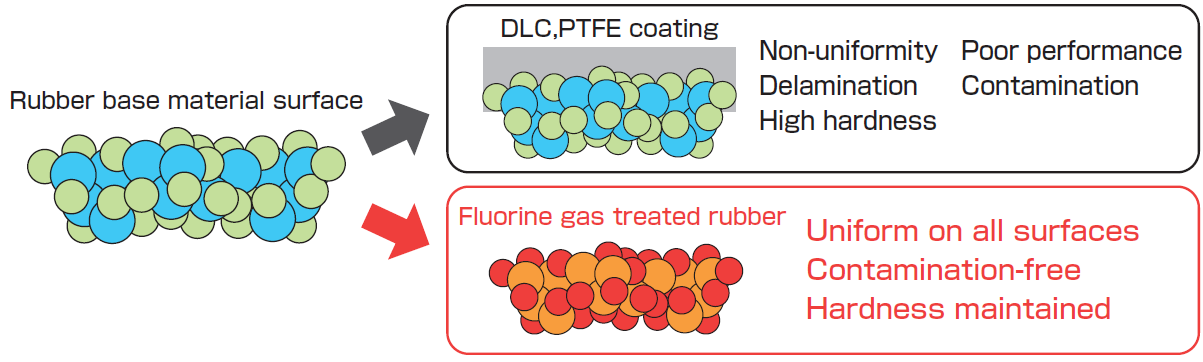

Non-tacky silicone trim” is a conventional “Silicone Trim®” product with high heat resistance, high chemical resistance, long life, and easy handling, which has been improved by innovative fluorine gas s urface t reatment to improve t ackiness, a characteristic of silicone rubber. The s ilicone rubber surface is chemically modified by contacting the silicone rubber surface with fluorine gas (vapor phase treatment), and because it is chemically modified rather than being a surface laminate coating such as DLC (hard carbon film) or PTFE (fluororesin) coating, it is more uniform, durable, and flexible than coated products. It also improves anti-adhesion performance and sliding properties, and improves adhesiveness, which is a characteristic of silicone rubber, reducing adhesion of dust and dirt.

Even after fluorine gas treatment, the chemical resistance, heat resistance, and flexibility of silicone trim can be

maintained at the same level as conventional silicone trim. The core structure of “silicone trim” allows for easy installation without the use o f adhesives. I t can also b e easily removed for easy m aintenance. The i nner core i s m ade of perforated stainless steel (SUS443), which offers superior rust resistance, flexibility, and safety. The cross-sectional lineup includes all the gray-colored part numbers of the conventional “Silicone Trim®” product. The product can be used in a variety of environments.

Features

Tack Resistance

By modifying the surface, it is

possible to reduce adhesion of

dust and dirt peculiar to silicone rubber.

Adhesion resistance

Reduction of sticking to mating

materials under special

environments or after long periods

of exposure is possible.

Easy Installation

Easy installation by simply

clamping onto a steel or plastic

plate. Since it bends freely,

installation at corners is also

easy.

Applications

It is used for packing of medical equipment, testing equipment, inspection equipment,food machinery, semiconductor manufacturing equipment, etc.

Silicone Trim® can be used in a wide range of applications.

Silicone Trim® is a registered trademark of Hotty Polymer Co. Ltd.

Fluorine gas treatment

03-3614-4100

03-3614-4100

To mail form

To mail form