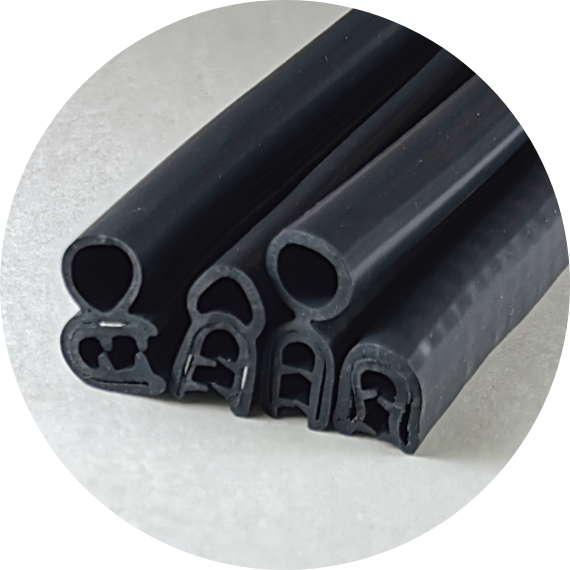

Silicone Trim® EN45545-2 compliant type

Silicone trim conforming to EN45545-2 (European Railway Vehicle Standard)

Silicone trim, which is easy to install and maintain,

now has a new specification conforming to

EN45545-2 R22/R23 (European Railway Vehicle Standard) .

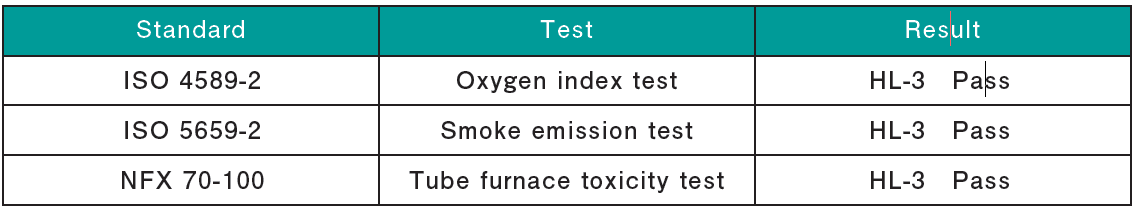

We have added a new series of One-Touch Easy & Convenience gasket silicone trims conforming to “HL (Hazard Level) -3”,

the most stringent of “EN45545-2 (European fire safety standard: combustion behavior requirements for materials used in railroad vehicles) R22/R23”.

The new series has excellent flame resistance and low smoke emission, and since it has been confirmed as compliant by a testing organization accredited under ISO/IEC17025, it can be easily adopted as gaskets and sealing materials.

The inner core is made of perforated metal made of stainless steel (SUS443), which excels in rust resistance, flexibility, and safety, and can be used in a variety of environments, such as outdoors and in places where it is difficult to handle. It can also be manufactured as a stand-alone product, not as a silicone trim.

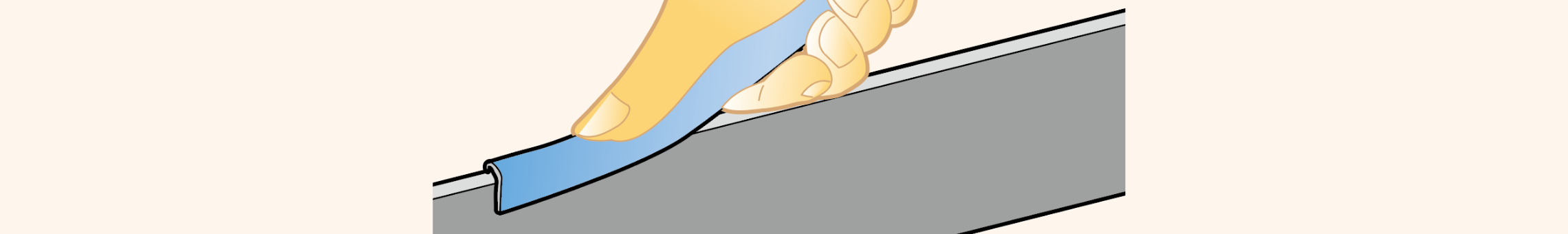

Easy installation without adhesive

Features

Rust resistance

Made of rust-resistant stainless steel (SUS443).

Length cutting is also easier to install.

Low smoke generation

Compared to general silicone

rubber, the amount of smoke

emitted is extremely low,

making it easier to maintain a

clear field of vision in the event of a fire.

Easy Installation

Since it is simply clamped

onto a steel or plastic plate,

it can be easily installed. It is

also easy to install at corners

because it bends freely.

Good maintenance

No adhesives are used, so no

contamination occurs.

It is also removable for easy

maintenance.

Applications

Gaskets and sealing materials for railway vehicles, packing and cable covers for testing equipment, electrical equipment, and inspection equipment, etc.

Silicone Trim® is a registered trademark of Hotty Polymer Co.Ltd

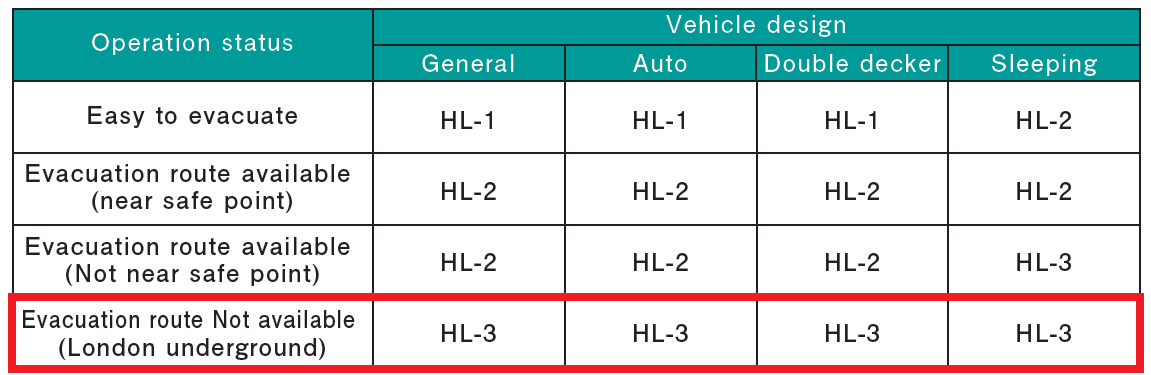

Ordinal Order of Risk Levels in the EN45545-2 standard

The higher the *HL (Hazard Level) value, the more severe.

EN45545-2 R22/R23 Test contents

*HL (Hazard Level) -3 is the most stringent standard in this test.

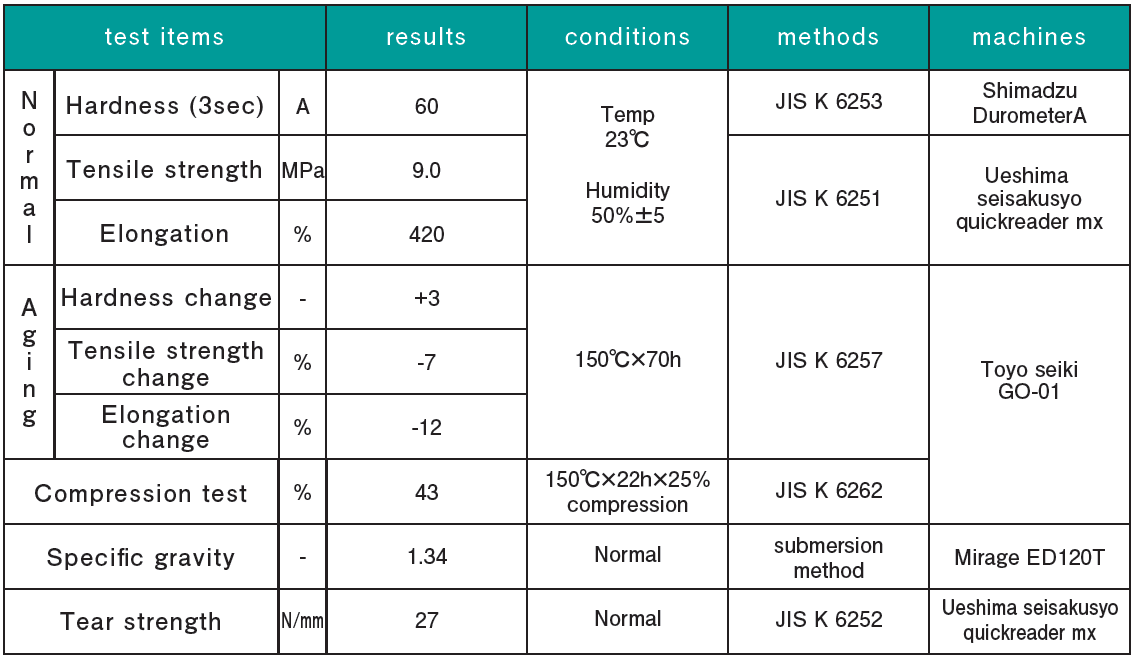

Basic Properties Table

Test conditions : Room temperature 25℃, humidity 50%.

Specimen preparation conditions: 2mm-thick sheet – 120℃ x 10 min, compression test ball – 120℃ x 15 min

Secondary vulcanization conditions: 200°C x 4h (same for both 2mm-thick sheet and compression test ball)

Tear strength test piece shape: Angle shape without incision

The physical properties values are representative values. It does not guarantee the physical properties.

03-3614-4100

03-3614-4100

To mail form

To mail form