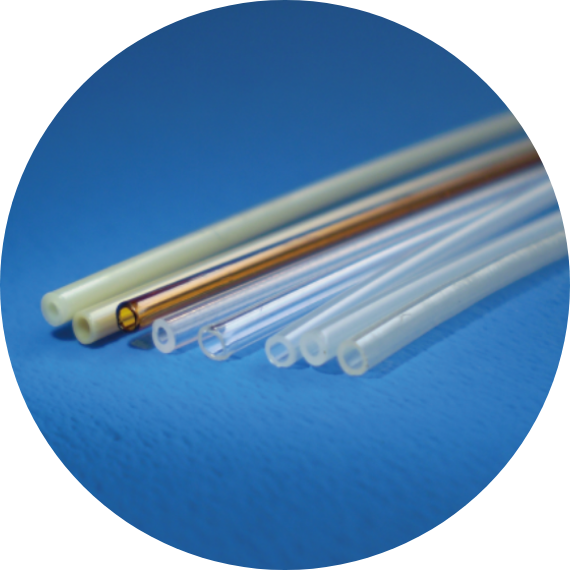

Ultra-thin Wall Super Engineering Plastic Tube Series

We offer various extrusions with various materials.

Manufacturable size (In outer diameter from 0.3mm to 3.0mm)

Please contact us about manufacturable wall thickness.

PEEK( Polyetheretherketone )

It is a super engineering plastic with excellent chemical resistance and heat

resistance. It can be used as metal substitution, because it has excellent hardness.

Features

Heat Resistance

Continuous use is possible at high

temperatures up to 260 C.

Friction Resistance

The friction coefficient of PEEK tube is very low.

Impact Resistance

PEEK tube retains its

toughness and

strength under

harsh conditions.

Flame resistance

PEEK tube has an inherent low flammability

(UL: V-0).

TPI ( Thermoplastic Polyimide )

It has excellent smoothness and eco-friendly. It also has excellent heat

resistance because its glass transition temperature (250°C)

is higher than other super engineering plastics.

Features

Heat Resistance

It can be used up

to 240°C.

Smoothness

Its kinetic friction coefficient is very low.

Eco Friendly

As compared to

other super engineering

plastics,it contains

less impurities and emits less gas.

Stability

It has excellent

plasma resistance,

radiation resistance,

and electrical properties

PPS ( Polyphenylenesulfide )

It has excellent mechanical properties. It meets the flammability requirements

of UL94 V-0. It has excellent resistance to acid, alkali, and organic solvents

at high temperature environment.

Features

Heat Resistance

Continuous use is

possible at high

temperatures

(170 – 200 °C).

Chemical Resistance

It has excellent

resistance to acid,

alkali, and organic

solvents at

temperatures

lower than 200 °C.

Chemical Resistance

It has excellent

resistance to acid, alkali and alcohol, etc.

Flame Resistance

It meets the

flammability

requirements

of UL94 V-0..

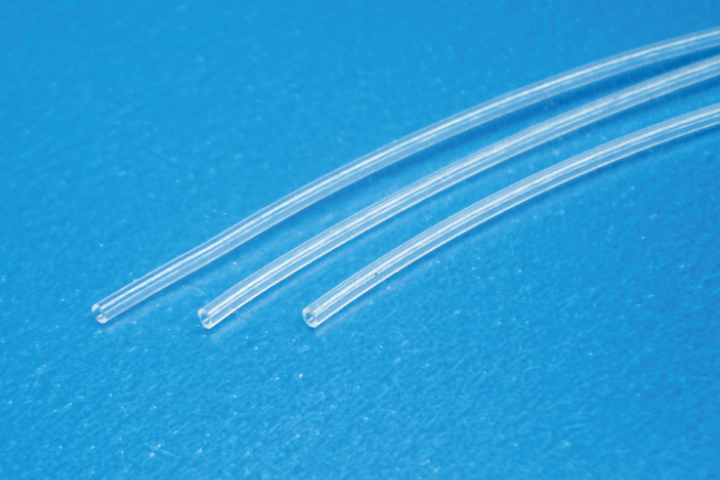

LM-ETFE ( Ethylene Tetrafluoro Ethylene Copolymer )

Fluororesin tube which has excellent heat resistance and transparency.

It shows excellent flexibility, heat resistance and transparency compared

to the conventional ETFE tubes.

Features

Heat Resistance

It can be used at temperatures ranging from

-200°C to 180°C.

Chemical Resistance

It shows exceptional

resistance to strong acids, alkalis, etc.

Flame Resistance

It meets the

flammability

requirements

of UL94 V-0.

Transparency

It has excellent

transparency

compared to the conventional

ETFE tube.

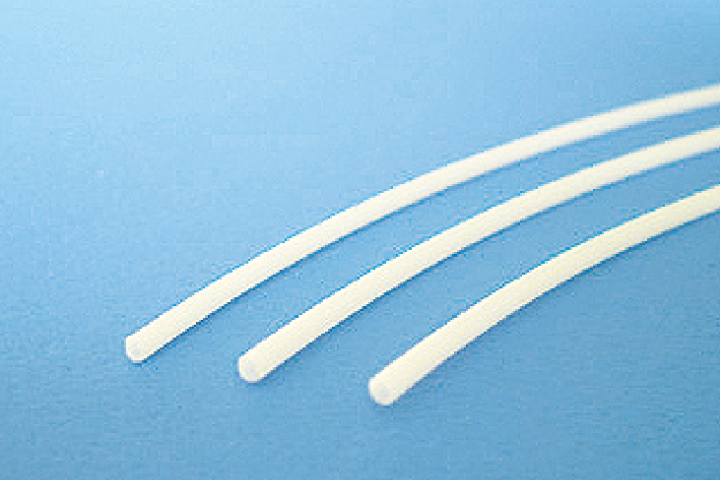

TPX® (Polymethylpentene)

It has excellent transparency, heat and chemical resistance. It also has excellent electric insulation, gas transmission rate and mold release characteristic.

Features

Heat Resistance

It can be used at

high-temperature

because its melting point is high.

Chemical Resistance

It has excellent

resistance to acids,

alkali and alcohol.

Low Specific Gravity

It can reduce the

weight of products

because its specific

gravity is the lowest

in thermoplastic

elastomers.

GasTransmission Rate

It has high gas

transmission rate because of its

molecule structure.

PA11 (Plant-derived Nylon 11)

It is made from castor oil that is distilled from castor beans. It has better

properties than Nylon6 and Nylon66 tubes.

Features

Temperature Property

It can be used at

temperatures

ranging from –40 °C to 130°C.

Flexibility

It has excellent flexibility.

Chemical Resistance

It has excellent

chemical resistance;

therefore, it is used for making car hoses,machines,

sewage pipes,etc.

Impact Resistance

It retains its properties at temperatures

lower than –40°C.

PA12 (Nylon 12)

It has special properties such as low-temperature characteristics, water resistance, weather resistance and impact resistance. It also has excellent electric insulation and gas transmission rate.

Features

Low-temperature Characteristics

It has excellent low-temperature characteristics compared with general nylons.

Weatherability

As compared to

general nylon

products,it has

excellent weather-ability.

Impact Resistance

As compared to

general nylon

products, it has

excellent impact

resistance.

Water Resistance

It has excellent water

resistance because the water absorption rate of the nylon 12 is approximately 1/7 of the water bsorption rate of nylon 6.

PC (Polycarbonate)

It has excellent properties such as transparency, heat and impact resistance.

Its visible light transmittance is as good as acrylic resin and it is self-extinguishing.

Features

Temperature Property

It can be used at

temperatures ranging from

–40 °C to 120°C.

Impact Resistance

It can retain its impact resistance at

temperatures lower than –40°C.

Flame Resistance

It is suitable for fire safety because it has

self-extinguishing

properties.

Transparency

Its visible light transmittance is as good as acrylic resin.

PGA (Polyglycolic Acid)

It has excellent gas barrier properties, abrasion resistance, and solvent resistance. It is also eco-friendly because it is biodegradable. It is decomposed into water and carbon dioxide in compost after one month. It can retain its properties at normal environmental conditions for one year.

Features

Eco-friendly

This tube is eco-friendly because it is

biodegradable.

Abrasion Resistance

It is a eco-friendly

product using

polylactic acid.

It can reduce the use of oil resource.

Gasbarrier Properties

This tube is eco-friendly because

it is biodegradable.

Mechanical Strength

It is environmentally

friendly because it does not emit CO2 and toxic gas.

PLA (Polylactic Acid)

It is a biodegradable thermoplastic aliphatic polyester by polymerizing lactic acid. It is an eco-friendly product and can reduce the use of oil resource.

Features

Eco-friendly

It is a eco-friendly

product because it is a biomass lastic.

Advancement

It is a eco-friendly

product using

polylactic acid.

It can reduce the use of oil resource.

Biodegradability

This tube is eco-friendly because

it is biodegradable.

Eco-friendly

It is environmentally

friendly because it does not emit CO2 and toxic gas.

03-3614-4100

03-3614-4100

To mail form

To mail form