Commitment to International Standards in

“Quality Assurance” and “Environmental Contribution” We have obtained two ISO certifications.

We are committed to delivering quality assurance and environmental contribution in accordance with international standards.

Quality Policy

To earn the trust and satisfaction of our customers at a high standard, we strive to provide the highest quality that exceeds customer expectations, and we continually make every effort to raise this level.

-

1.

It is essential to appropriately respond to customer requirements and provide maximum satisfaction. -

2.

We set quality objectives, review them regularly, and work toward achieving them. -

3.

We establish and implement a quality management system, continuously improving its effectiveness. -

4.

We comply with all relevant laws, regulations, and other applicable standards.

Production Environment

Formulation Technology and Research & Development

Although the products we handle are generally referred to as rubber and resin, they actually encompass a wide variety of materials, including natural rubber, synthetic rubber, silicone rubber, fluororubber, and thermoplastic elastomers, as well as synthetic resins.

These materials require specific physical properties (such as flame retardancy or conductivity) depending on their intended applications, which demands comprehensive research into formulation from various perspectives.

Furthermore, key research and development themes include enhancing functionality, reducing costs, and promoting recycling.

We continuously strive to stay ahead of market needs by accurately identifying trends and applying forward-thinking concepts and innovative creativity to our research and development efforts.

Twin-Screw Extruder

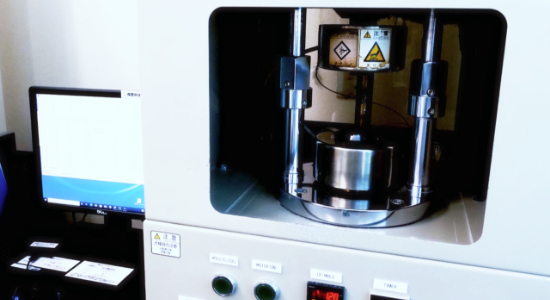

Curelastometer

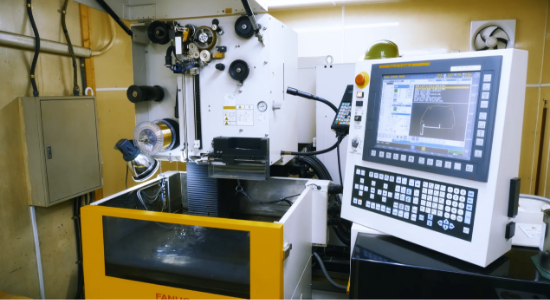

Die Design and Manufacturing

Through 100% in-house quality control and flexible design concepts linked to production technology, we have established innovative die design technologies.

Wire Electrical Discharge Machine

NC Milling Machine

Production Line

Under the philosophy that “as materials evolve, production lines must evolve as well,” we remain committed to keeping an eye on the latest cutting-edge technologies and equipment.

Looking ahead to the new era, we are also actively engaged in research utilizing new materials, recycling, and nanotechnology.

State-of-the-Art Resin Extrusion Line

Rubber Continuous Vulcanization Extrusion Line

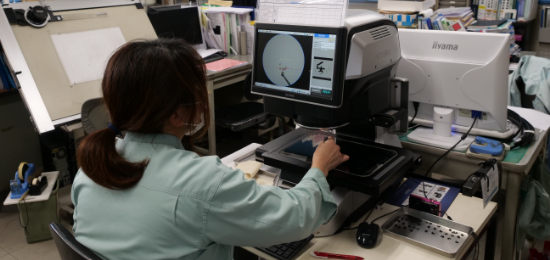

Testing Equipment

Inspection capabilities that support advanced technology with robust testing equipment

Hotty Polymer is equipped with testing facilities that support advanced technology. These include microscopes, universal testing machines, a quick reader semi-automatic tensile testing machine, Mooney viscometer, ozone weather meter, and other comprehensive testing equipment.

List of main testing equipment

| Quick Reader Semi-Automatic Tensile Testing Machines | 1 unit |

|---|---|

| Mooney Viscometers | 1 unit |

| Ozone Weather Meters | 1 unit |

| Conductive Resistivity Meters | 1 unit |

| Universal Projectors (5x, 10x) | 8 units |

| Ultrasonic Internal and External Diameter Measuring Devices | 1 unit |

| Microscope and Measurement Processing Systems | 3 units |

| Gear-Type Aging Testing Machines | 3 units |

| Rubber Hardness Testers (Durometer A) | 10 units |

| Infrared Surface Thermometers (0–200°C) | 6 units |

| Stereo Microscopes (80x) | 1 unit |

| Testing Rolls (8×18 inches) | 1 unit |

| Ultrasonic Cutters | 1 unit |

| Plasma Treatment Machines | 1 unit |

| Various 3D Printers | 25 units |

|

Shimadzu Autograph with CT-Type Compression Bending Test, DTF-Type Elongation Measurement, and AG-Type Compression Test Data Processing System |

1 unit |

|---|---|

| Curelastometer Type 2 FB | 1 unit |

| Melt Indexers | 1 unit |

| High-Resistance Insulation Meters | 1 unit |

| Laser Outer Diameter Measuring Devices | 2 units |

| Electronic Densimeters | 3 units |

| Keyence Image Measures: | 2 units |

| Low-Temperature Testing Machines | 1 unit |

| Sponge Hardness Testers (Durometer E) | 4 units |

| Surface Thermometers (–200 to 800°C) | 1 unit |

| Thickness Gauges | 4 units |

| Dumbbell Punching Devices | 1 unit |

| Tackiness Checkers | 1 unit |

| Twin-Screw Mixing Pelletizer Lines for Material Development | 1 unit |

Environmental Policy

We aim to balance environmental conservation with business activities by implementing environmental management practices, continuously improving them, and contributing to society, enhancing satisfaction for our business partners, and increasing satisfaction for all employees.

-

1.

We will promote energy and resource conservation activities, and recycling of rubber and resin. -

2.

We will strive to reduce waste from rubber, resin, and packaging materials. -

3.

We will set environmental objectives and targets, strive to achieve them, and regularly review them for continuous improvement. -

4.

We will comply with relevant environmental laws, regulations, and other requirements agreed upon by the company, and work to prevent pollution. -

5.

We will ensure that all employees are fully informed of this policy and make it publicly available.

Environmental Initiatives

Our company obtained the environmental standard ISO 14001 in fiscal year 2004 (Kuki Factory) and has been engaged in environmentally friendly production activities. Below are some of the initiatives we are undertaking.

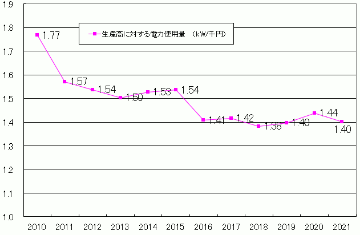

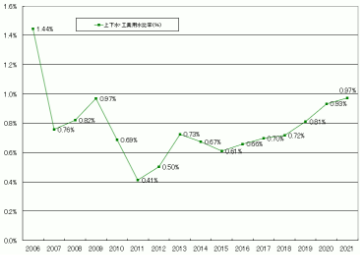

Electricity Cost Ratio

Reduction of Electricity Consumption

Efforts to reduce electricity consumption are based on the previous year’s electricity usage per production output at the Kuki Plant. In recent years, the impact of global warming has led to an increase in electricity consumption during the summer months. Our company has set a reduction in electricity usage, converted into CO2, as an environmental goal and is working on reducing consumption through demand management along with other efforts.

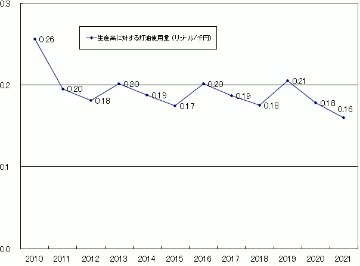

Kerosene Cost Ratio

Reduction of Kerosene Consumption

Efforts to reduce kerosene consumption are based on the previous year’s kerosene usage per production output at the Kuki Plant. In fiscal year 2010, the ratio was 0.26, and through improvement activities, this has been reduced to 0.16 in fiscal year 2021.

Our company has set a reduction in kerosene usage, converted into CO2, as an environmental goal and is actively working to reduce consumption. /p>

Water Supply, Wastewater, and Industrial Water Ratio

Reduction of Water Supply, Wastewater, and Industrial Water

Efforts to reduce water supply, wastewater, and industrial water consumption are based on the previous year’s water supply, wastewater, and industrial water charges per production output at the Kuki Plant. In recent years, there has been a gradual increase in usage due to the expansion of equipment. Our company has set a reduction in water supply, wastewater, and industrial water usage, converted into CO2, as an environmental goal and is actively working to reduce consumption.

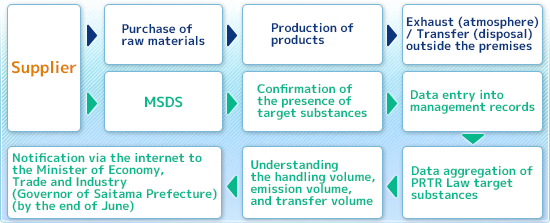

Management of Environmental Hazardous Substances (Response to the PRTR Law)

In accordance with the PRTR Law (Pollutant Release and Transfer Register Law), “Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof,” which was enacted in July 1999, our company submits reports based on the law’s requirements.

Fiscal Year 2023 Environmental Hazardous Substance Transfer and Emission Status (April 2023 – March 2024)

| Legislative Number | CAS Number | Chemical Substance Name | Handling Volume (kg/year) | Transfer Volume (kg/year)*1 | Emission Volume (kg/year)*2 |

|---|---|---|---|---|---|

| 355 | 117-81-7 | Bis(2-ethylhexyl) Phthalate | 912 | 15.9 | 1.8 |

| 452 | 149-30-4 | 2-Mercaptobenzothiazole | 661 | 18.9 | 1.3 |

*The data was calculated based on the PRTR Class I designated chemical substances with annual handling volumes of 1 ton or more.

*1 Transfer volume to locations outside the facility

*2 Emissions released to the atmosphere

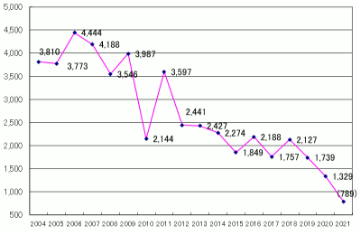

PRTR Substance Handling Volume Trends

This graph shows the handling volume trends of PRTR-regulated substances from fiscal year 2004 to 2023.

Our company is committed to developing and using environmentally friendly raw materials and promoting the reduction of environmentally hazardous substances.

Bis(2-ethylhexyl) phthalate, except for certain formulations required by specific customers, has been completely replaced with alternative materials in all of our developed formulations.

In fiscal year 2021, the handling volume fell below 1 ton, and the substance was excluded from the PRTR regulations.

03-3614-4100

03-3614-4100

To mail form

To mail form