We will propose materials and modeling methods that meet your needs with 3D printers that will change the way you think about manufacturing.

-

LAM

Silicone Rubber

3D Printing Services -

MEX

SLA/LCD

3D Printing Services -

MEX

Super Engineering plastics

3D Printing Services

Silicone Rubber 3D printing Services

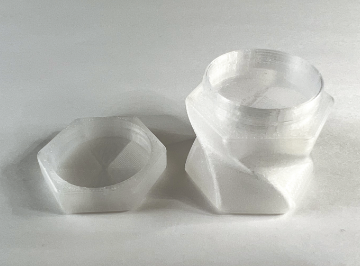

We can meet the needs for small volume production by using the LAM method silicone 100% 3D printers “SILICOM” and “LiQ320” and simple resin mold production. Cross-linked Bonding® modeling offers unlimited possibilities!

in the past, the production of silicone rubber prototypes and small-scale manufacturing was typically done through the fabrication of prototype molds and cutting processes for rubber sheets. However, we have now developed 3D printing services for silicone rubber object using LAM (Liquid Additive Manufacturing) 3D printers such as “SILICOM” and “LiQ320,” as well as the production of simplified resin molds through 3D printing. In the case of cutting processes, significant material waste can occur as the flat material is machined into shape. Moreover, the high cost of mold production makes it difficult to carry out prototyping using traditional mold-making methods. With our 3D printing services, we employ the LAM method to significantly reduce material waste and lower costs. Our unique “cross-linking bonding (patented)” technology enables us to create various shapes with ease. Additionally, producing simplified resin molds through 3D printing is more cost-effective than producing prototype molds using materials like aluminum. Please inquire about our ability to accommodate specific shapes, as feasibility may vary depending on the shape.

LAM method 3D printer (SILICOM) (LiQ320) contract processing

Materials are UV-crosslinked liquid silicone rubber or thermally crosslinked DOW SILASTIC TM LSR.

The UV-crosslinked type has a hardness of 30° (JISA)

The thermally crosslinked type has a hardness of 50° (JISA)

The UV cross-linked type can be colored (any physical properties are acceptable. Please consult with us.) Furthermore, through combination fabrication using cross-linking bonding, it’s possible to create various shapes while maintaining strength.

-

Heart Model (Cross-Linked®)

-

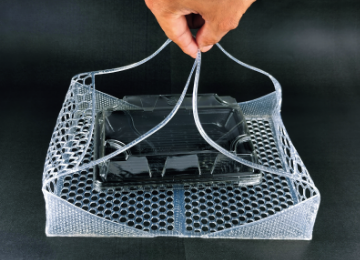

Eco Bag (Cross-Linked®)

-

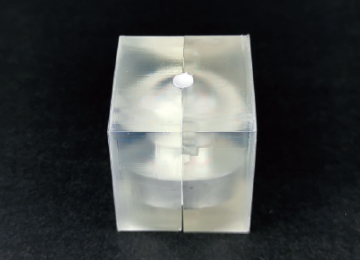

Hollow Product

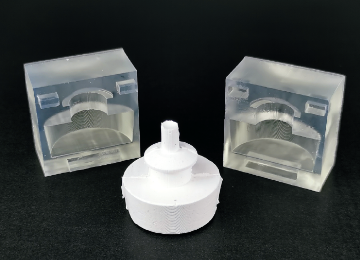

Contract processing by simple resin mold production

This method involves creating a simple resin mold using a 3D printer, injecting liquid silicone, and curing it.

-

① Simple Resin Mold created by 3D Printer

-

②Inject liquid silicone

-

③Completion of products

SLA/LCD

SLA/LCD

3D Printing Services

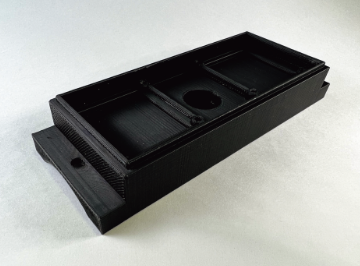

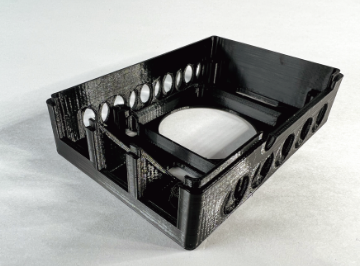

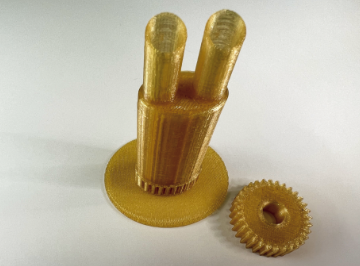

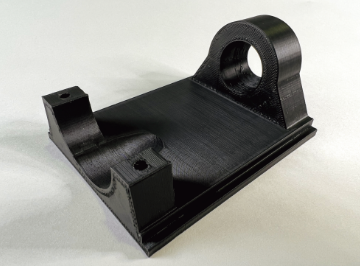

We offer contract manufacturing of molded products in various materials using MEX and SLA/LCD 3D printers.

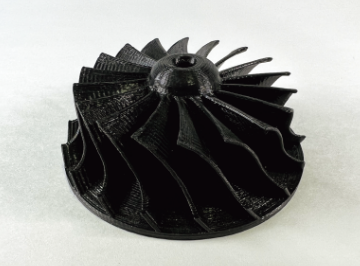

When prototypes are made by cutting, large material losses are incurred depending on the shape of the prototype, since they are made by cutting round bars and flat plates, which are the raw materials for the prototypes. Our 3D printing service uses the MEX and SLA/LCD method, which significantly reduces losses and costs. In addition, 3D printers can make the inside hollow or honeycomb shape, so it is possible to reduce material costs and weight compared to machining. Therefore, it is possible to produce shapes that cannot be produced by cutting. We also have a 3D printer capable of manufacturing long products, which enables us to produce 3D modeling of hard extruded products prior to mold making. We can also add surface embossed pattern using our advanced engineering software “nTop” to make it difficult to see layer marks and to add design to the product. Please contact us for details.

Product Lineups

MEX 3D printer

A wide variety of materials are available for the MEX, with a maximum build size of 1000×1000×1000 mm.

General materials

-

PLA

-

ABS

-

PC

-

PA

-

PP

-

TPU (90A)

-

FABRIAL®

-

SMP

-

Onyx(PA+CF)

HP Filament®Series

-

Flexible (60A/75A)

-

High strength PLA

-

PEEK

-

PEI(ULTEM™)

-

PPS

-

XYRON240Z

-

HYTREL®SC-753

-

PERPRENE®PB-40

-

DURABIO™

-

Flexible phosphorescent

-

WOOD PLA

-

UV Reactive PLA

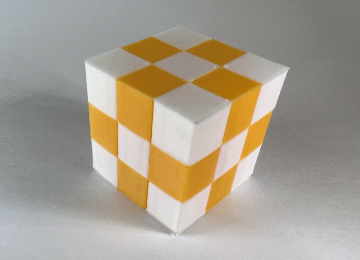

Dual printing

Dual printing with different colors in each material and dual printing with HP filament (super flexible type, flexible type) and PLA are possible.

-

HPF(SFT)+PLA

-

HPF(SFT) two colors

-

PLA two colors

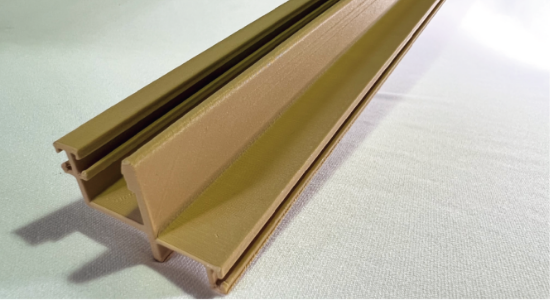

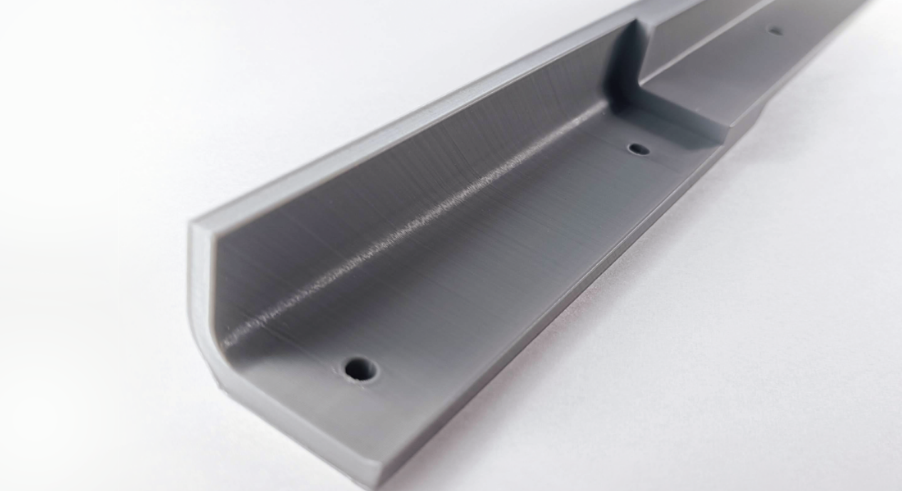

Long object printing

We have a special 3D printer that is capable of producing long objects (max. approx. 3000 mm).This printer allows us to conduct secondary processes such as drilling and notching, as well as perform checks prior to the creation of press molds for secondary processing. This offering is unique to us as an extrusion manufacturer providing contract manufacturing.

Compatible materials: PLA, ABS (depending on the shape)

Sample of secondary processing (drilling, notching)

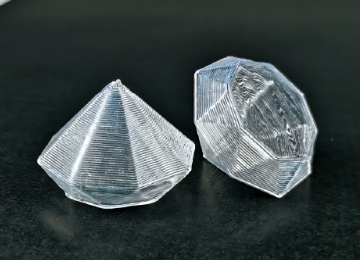

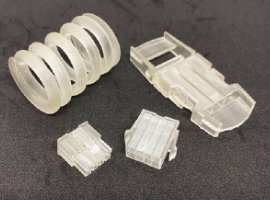

SLA/LCD method 3D printer

Compatible resin (Acrylic)

-

General industrial resin

-

ABS resin

-

Rubber-like (50A)

-

Casting material

Services common to all printing methods

3D scanning

We use the 3D scanner “Einscan” to scan the actual object, convert it into data, and then use a 3D printer to create the object.

A 3D scanning and data creation fee will be charged for this service.

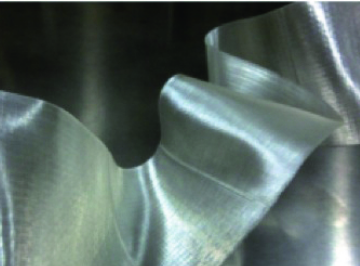

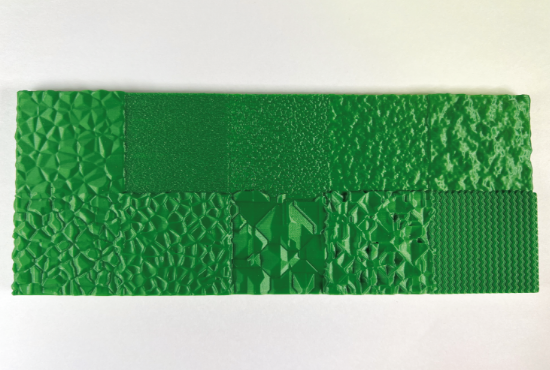

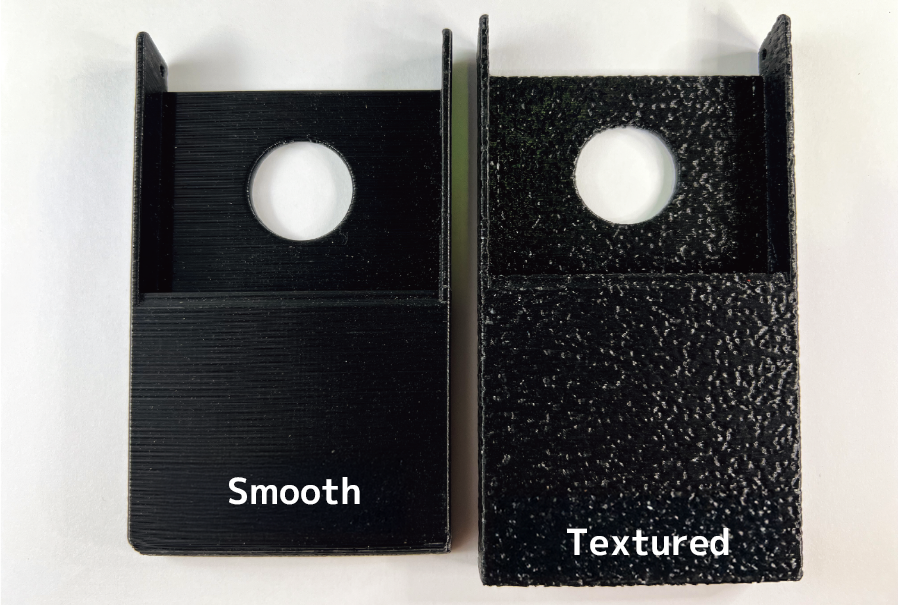

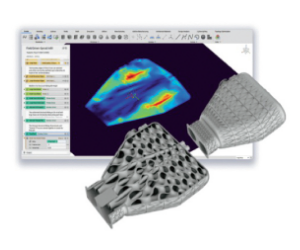

Texture (embossed pattern etc.) by nTop

Using the DfAM software “nTop,” we can add embossed pattern and textures to the surface of 3D printed objects to make layer marks less noticeable and to add design to the object. We can also reflect the requested embossed pattern on the product. Please contact us. A data preparation fee is required for this service.

Points to be noted

・When placing an order, kindly provide us with the 3D CAD data.

Data created in 3D CAD should be submitted in STL format (.stl). If you have data in other formats, please consult with us.

・Layer lines may remain visible on the finished surface. Regarding polishing finishes, please discuss this separately.

Super Engineering Plastics

3D printing services

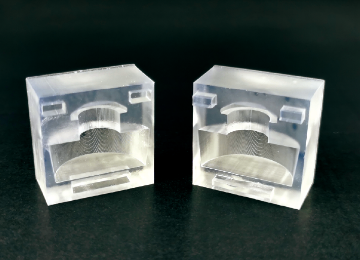

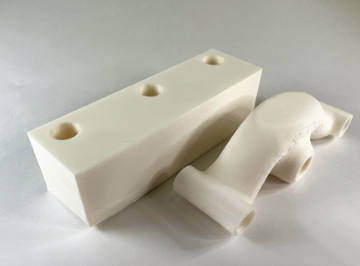

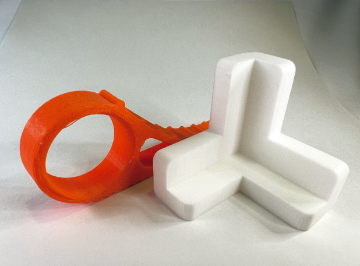

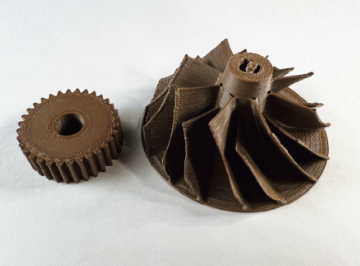

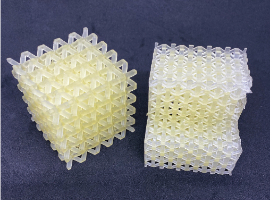

We can produce small-lot production of super engineering plastics (PEEK, PEI (ULTEMTM), PPS), for which machining is the mainstream process, using a MEX 3D printer.

In the production of 3D products made of super engineering plastics, injection molding is the mainstream for large-lot production, and cutting is the mainstream for small-lot production.

We offer contract manufacturing of 3D products made of super engineering plastics such as PEEK using our MEX 3D printer with our filaments. In the cutting process, round bars and flat plates, which are the raw materials for the products, are cut and fabricated, resulting in a large loss depending on the shape.

Our 3D printers use the MEX method, which significantly reduces losses and costs. In addition, the 3D printer can make the inside hollow or honeycomb shape, which reduces material costs and weight compared to machining, which can only produce solid materials.

Therefore, it is possible to produce shapes that cannot be produced by machining.

・PEEK (polyetheretherketone) ・・・ ①Victrex 450G, ②Daicel-Evonik L4000G, ③PFLUON 8100G

・PEI (Polyetherimide) ・・・ ①ULTEMTM 1010-1000, ②9085-1100

・PPS (Polyphenylene sulfide) ・・・ DIC FZ2100

We can produce 3D printer molded products in the above materials.

Please contact us for details.

Features

-

Economical

No material loss due to cutting,

resulting in superior cost performance. -

Lightweight

The interior can be made hollow or honeycombed,

which allows for weight reduction.” -

Diversity

We offer a wide selection of materials

to suit your application and use,

including PEEK, PEI, and PPS materials,

as well as PEEK materials by manufacturer. -

Advanced Capability

The use of the MEX method allows

for the production of shapes

that are not achievable through

conventional machining processes.

Applications

Elemental development of products related to automobiles, electronics, analytical instruments, scientific instruments, semiconductors, medical equipment, etc. (Detailed discussions are required for mass production adoption.)

Leave it to us for anything related to 3D printers!

We provide comprehensive support for your needs, from 3D printer hardware to filaments, tailored to your fabrication requirements. Additionally, we offer experienced technical support for contract and processing services, adapting flexibly to your specific requests. Feel free to contact us anytime.

03-3614-4100

03-3614-4100

To mail form

To mail form