Developing, Manufacturing, and Selling Filaments for Your Specific Needs and Applications

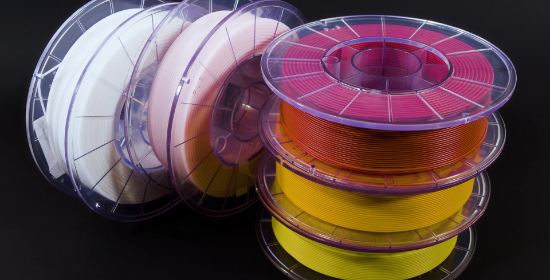

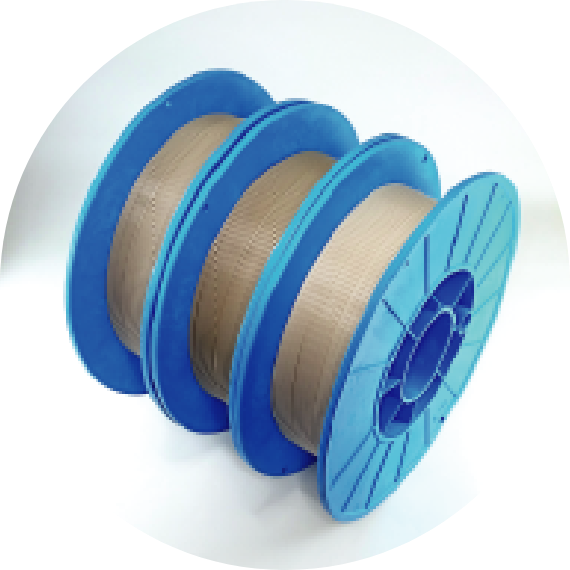

The materials used in 3D printers such as MEX (Material Extrusion) and FDM (Fused Deposition Modeling) are synthetic resin filaments. Filaments are thread-like materials with distinct characteristics in terms of material type, size, and more.

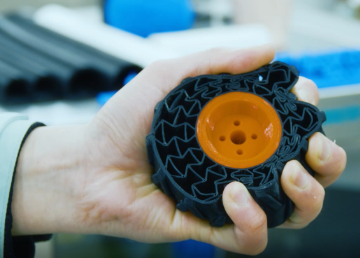

In recent times, the variety of filament materials has expanded, enabling 3D printers to create not only prototypes but also functional and final products. With the growing diversity of materials, possibilities extend to the development of architectural components, mechanical parts, household appliances, and more. This could potentially accelerate the creation of products featuring unprecedented designs and innovative functionalities.

Choosing Materials for Use in 3D Printing

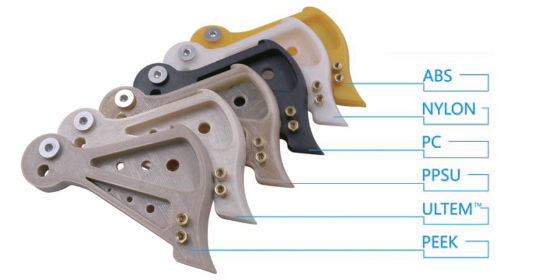

When selecting materials, various considerations are necessary based on the shape of the object (size, finishing, etc.) and its intended use (functional, decorative, business, etc.).

・Print Precision

・Strength

・Availability of Coloring

・Possibility of Polishing

・Environmental Conditions

(indoor/outdoor, high/low temperatures, etc.)

・Additional characteristics like

“aromatic,” “luminous,” or “high-strength” are also possible.

There are various manufacturing methods within 3D printers, ranging from user-friendly options suitable for home use to high-performance models utilized by industries and businesses. Different types of 3D printers are available, catering to a wide range of applications. Furthermore, the materials that can be used and the characteristics of these materials vary depending on the manufacturing method and the model of the 3D printer. In other words, selecting the appropriate ‘3D printer model’ based on the intended purpose and application of the desired creation is essential, and it is equally important to have a solid understanding of the characteristics of the available materials for the proper ‘material selection’.”

Leave it to Hotty Polymer!

Consistent support for more reliable 3D printer modeling based on our extensive experience and achievements in extrusion technology cultivated over many years

With a long history of extrusion products of rubber, resin, and polymeric materials as its core business, HOTTY POLYMER was founded in 1948 as HOTTA RUBBER INDUSTRY. Over the years of research and manufacturing, our high-performance rubber extrusion products and high-performance resin extrusion products have earned a reputation for high quality and high reliability in a wide range of fields, including construction materials and automotive applications.

Based on our extensive experience and achievements cultivated over the years, we are able to offer more reliable 3D printer modeling, from material selection to completion, which only Hotty Polymer can provide.

Leave it to us for anything related to 3D printers!

We provide comprehensive support for your needs, from 3D printer hardware to filaments, tailored to your fabrication requirements. Additionally, we offer experienced technical support for contract and processing services, adapting flexibly to your specific requests. Feel free to contact us anytime.

03-3614-4100

03-3614-4100

To mail form

To mail form