Skinless Foam

Innovative rubber extruded sponge product without skin layer

Skinless foam is a revolutionary extruded foam rubber that

does not have a surface layer (skin layer),

which is usually attached to extruded products.

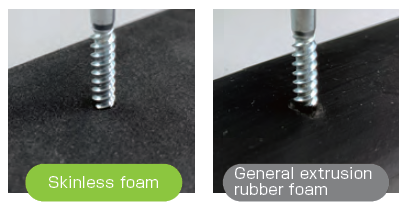

Generally, a skin layer is always formed on the surface layer of foam products extruded by linear hot-air vulcanizing equipment when hot air is used to mold them. Skinless foam is a revolutionary product that overturns this basic concept. Despite the absence of a skin layer, its unique foam structure results in low water absorption, effective heat insulation and sound insulation, and excellent shock absorption. In addition, because of the skin layer, general foam products are usually drilled with a punch or similar tool before drilling, because the skin layer causes the sponge to wrap around the drilled hole (see the photo on the right). However, skinless foam does not have a skin layer and can be drilled as is, thus reducing processing costs. The material is EPDM, and

hardness is approximately 40° (JIS E). Please feel free to contact us.

Drilling

Features

Shock Absorption

Special foam structure provides

excellent shock absorption.

Secondary processability

No skin layer provides

excellent machinability in

drilling and other processes.

Low water absorbency

Water absorbency is as low as

2%, which is about the same

as common EP foam products.

Saving money

Drilling is no longer required,

reducing secondary machining

costs.

Application

Gaskets, packing, sealing materials, sound absorbing materials, heat insulating materials, etc. that require secondary processing in construction, civil engineering, etc. Applications are wide-ranging and diverse.

03-3614-4100

03-3614-4100

To mail form

To mail form