SILICOM

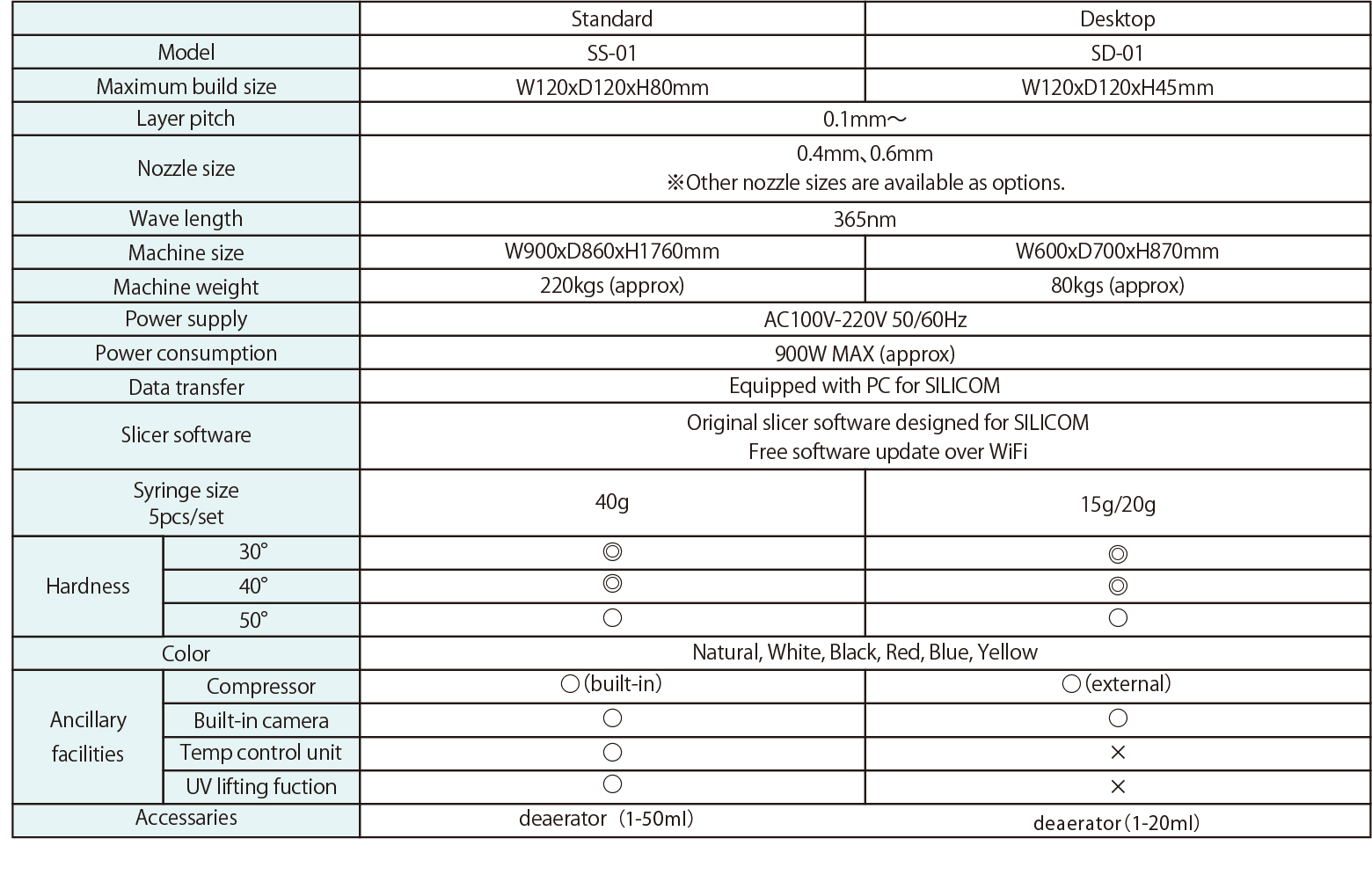

Standard Type SS-01 / Desktop Type SD-01

Groundbreaking new model enabling 3D shaping with 100% silicone rubber

Case study

SILICOM Case Study: Robotic Hand

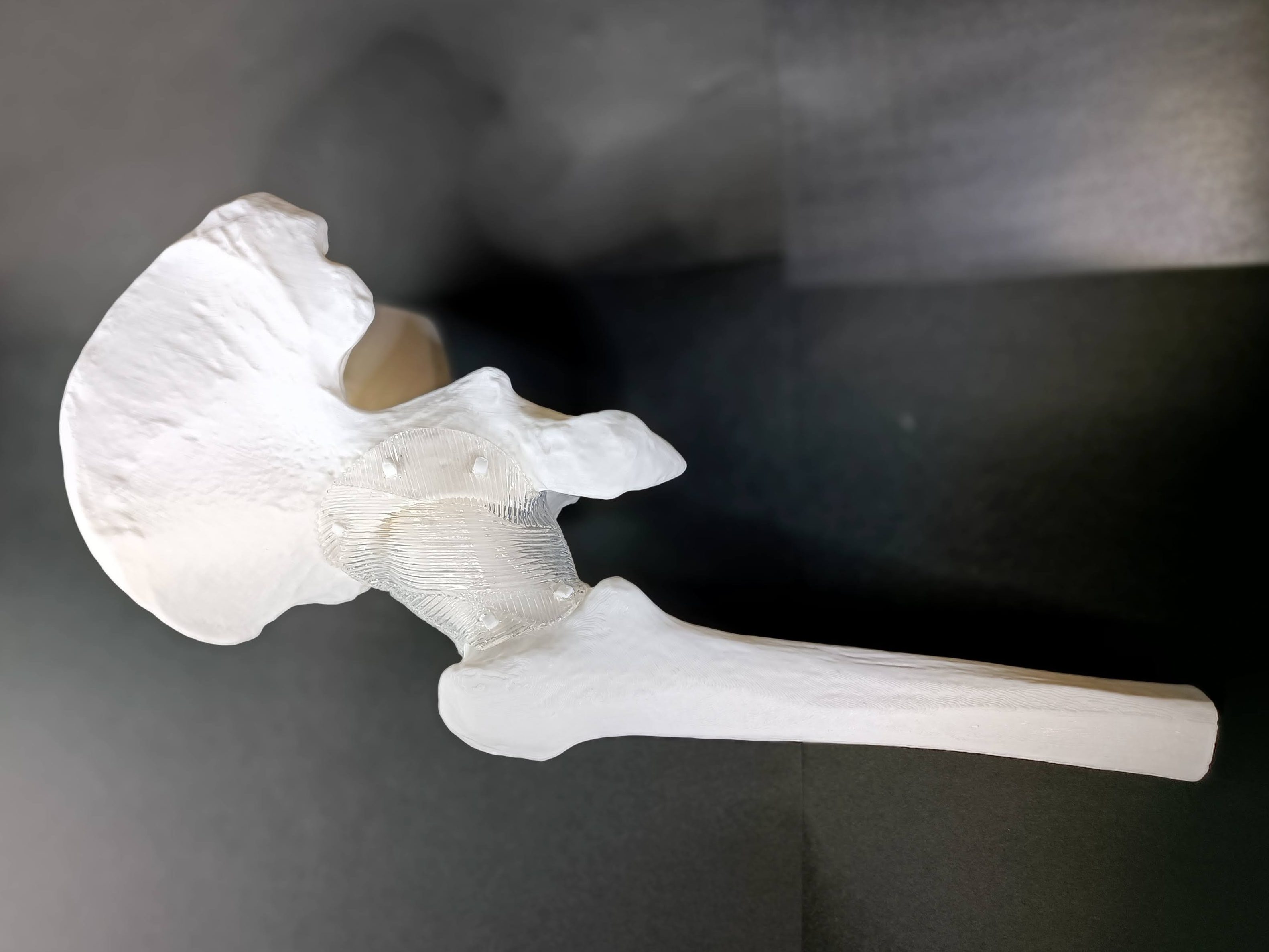

SILICOM Case Study: Joint Capsule Model

“SILICOM” is a silicone rubber 3D printer that expands the new possibilities of silicone rubber 3D printing, using a UV-curable liquid additive manufacturing (LAM) method.

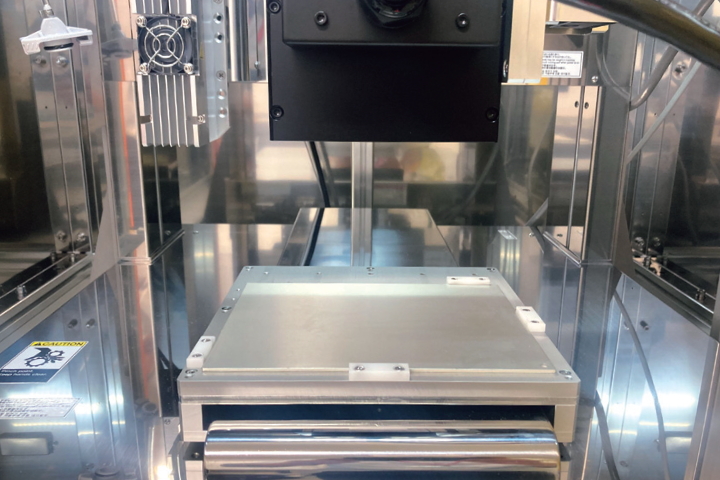

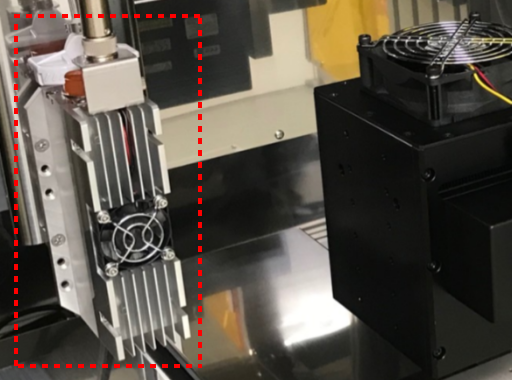

Product photo

Standard Type SS-01

Desktop Type SD-01

Build area Standard model

[AI-powered] Equipped with in-house developed slicer software

The information provided is as of June 24, 2024, and may be subject to change without notice.

This product is a patented item (Patent Numbers: 7158787, 7121435, 6949187).

Features

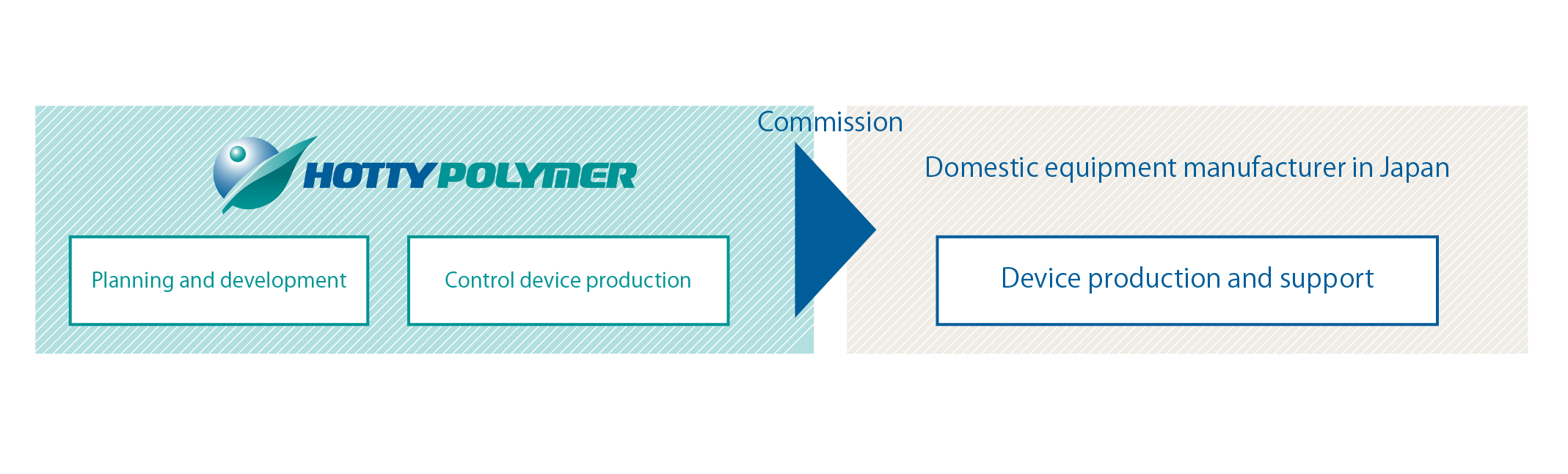

Reliable supply and warranty system through domestic production in Japan

Syringe method adopted for material supply

The material supply uses a UV-blocking syringe method, allowing easy setup changes and flexible material development.

Available syringe capacities: 10ml, 20ml, 50ml.

Patent granted.

Available in a range of hardness levels, from low to high.

SILICOM allows you to choose hardness levels, unlike other soft 3D printing methods.

Additionally, physical properties such as tensile strength can be achieved at levels equivalent to those of molded products.

Current hardness lineup

| 30° | 40° | 50° |

In development hardness

| 10° | 20° | 60° |

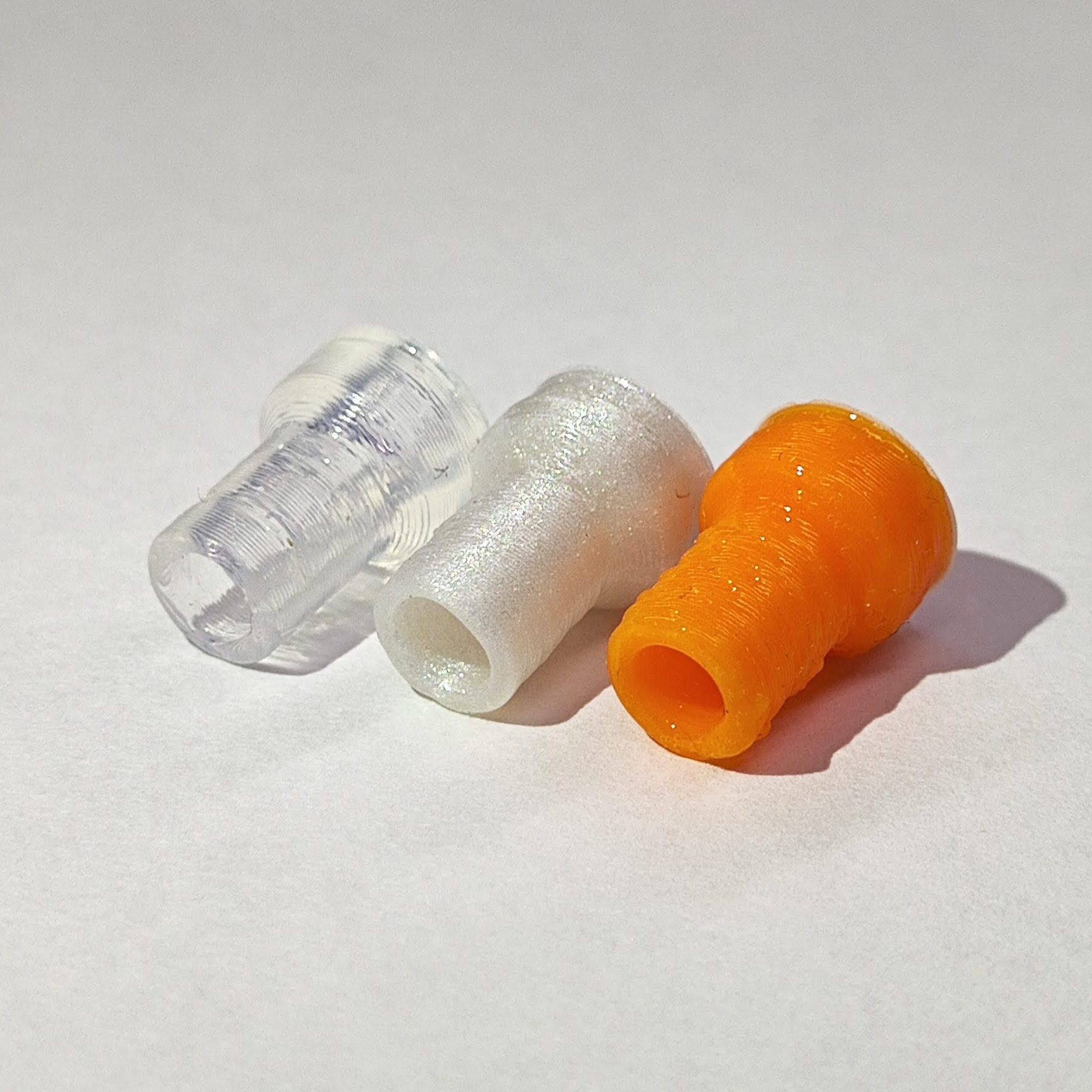

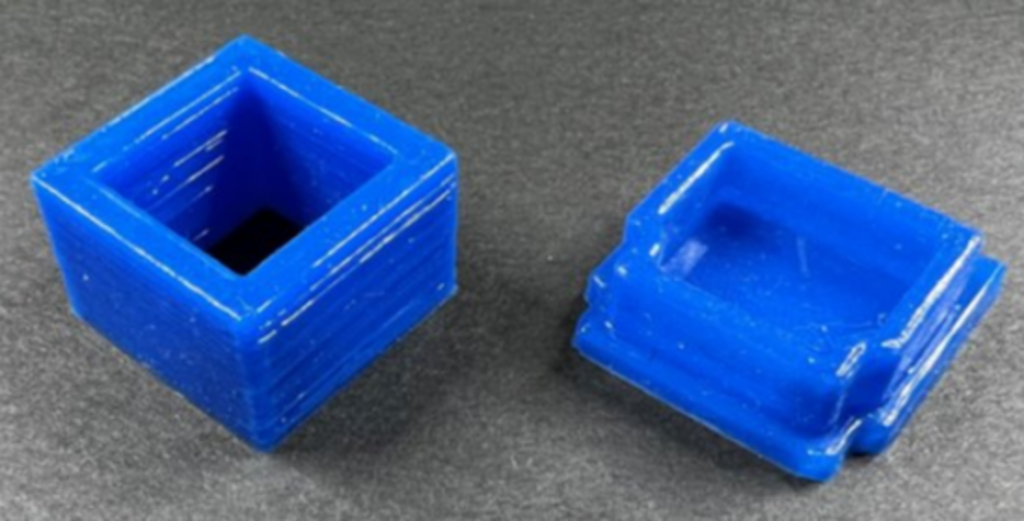

Color options available, including custom colors.

■Standard colors: 6 colors – Natural, White, Black, Red, Blue, Yellow *Custom colors also available.

Coloring is achieved by adding pigments to the natural liquid silicone rubber.

Color adjustments can be made per syringe (10ml, 20ml, 50ml).

Natural color

Naural + Insert

Color samples for the medical field

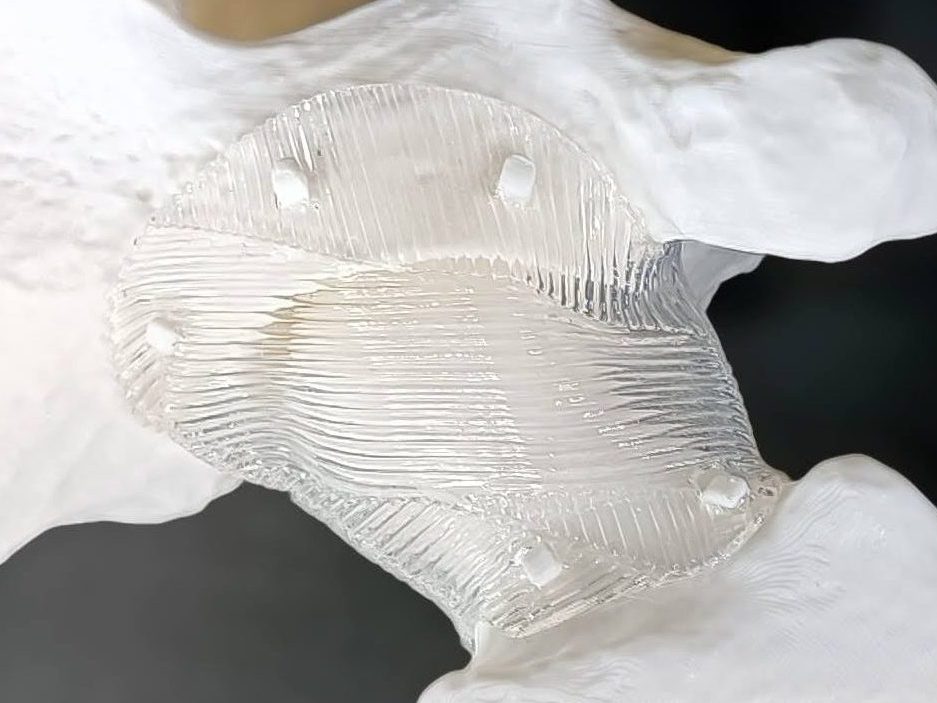

We present the adoption example of a “Bone Model + Fascia Shape (Crosslinked Joint Product).”

(For Johnson & Johnson)

The fascia shape is used for suture testing, while the bone shape is a PLA 3D printed product.

Explanation of “Crosslinked Joint” is provided at the bottom of this page.

<Bone Model + Fascia Shape (Crosslinked Joint Product)>

Enlarged view: At the request, the fascia muscles are also represented.

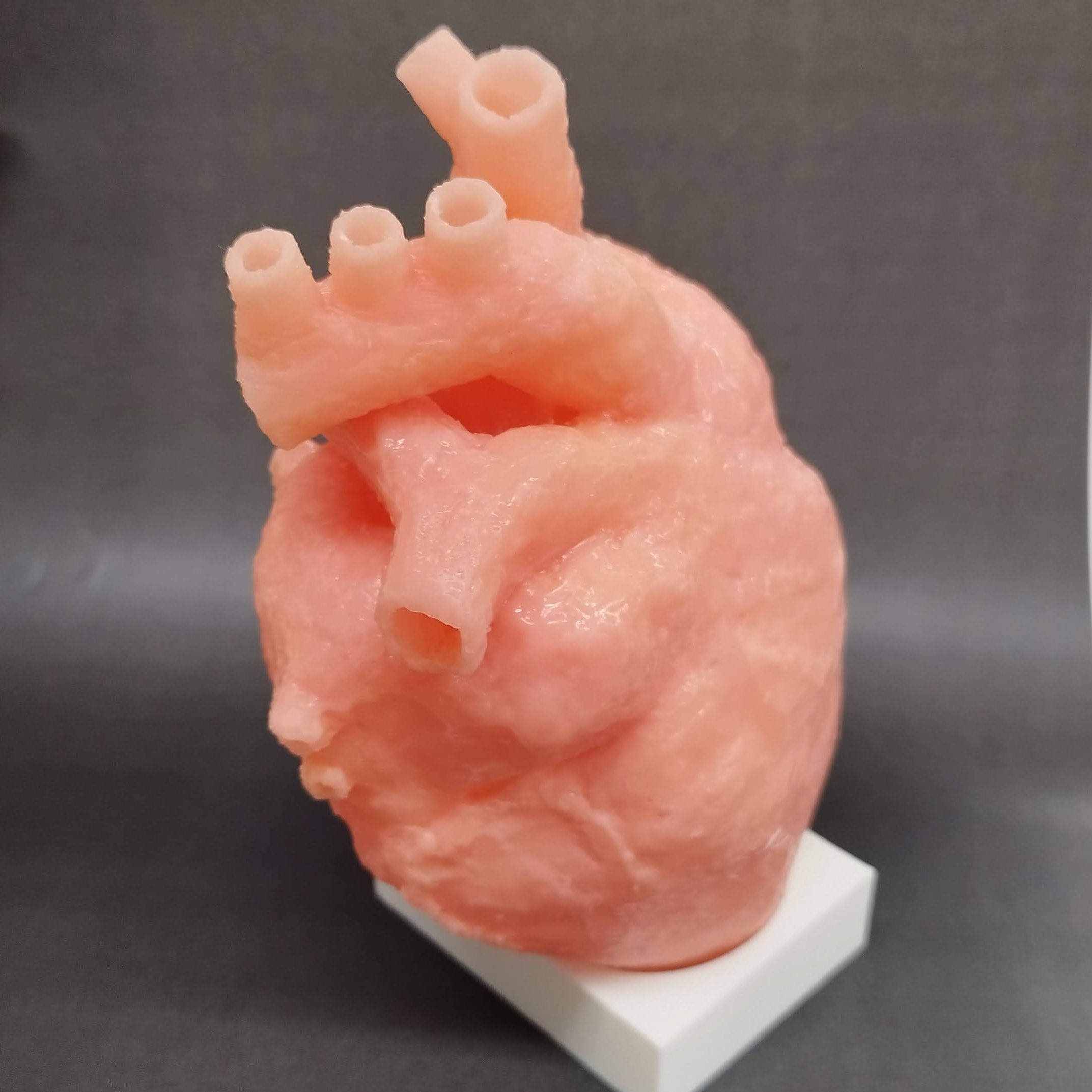

<Heart Model (Crosslinked Joint Product)>

<Blood Vessel Model (Crosslinked Joint Product)>

Longer models can also be produced

<Ear Shape>

<Tooth + Gum Shape>

The tooth is a SLA product.

<Heart Model>

Crosslinked joint applied.

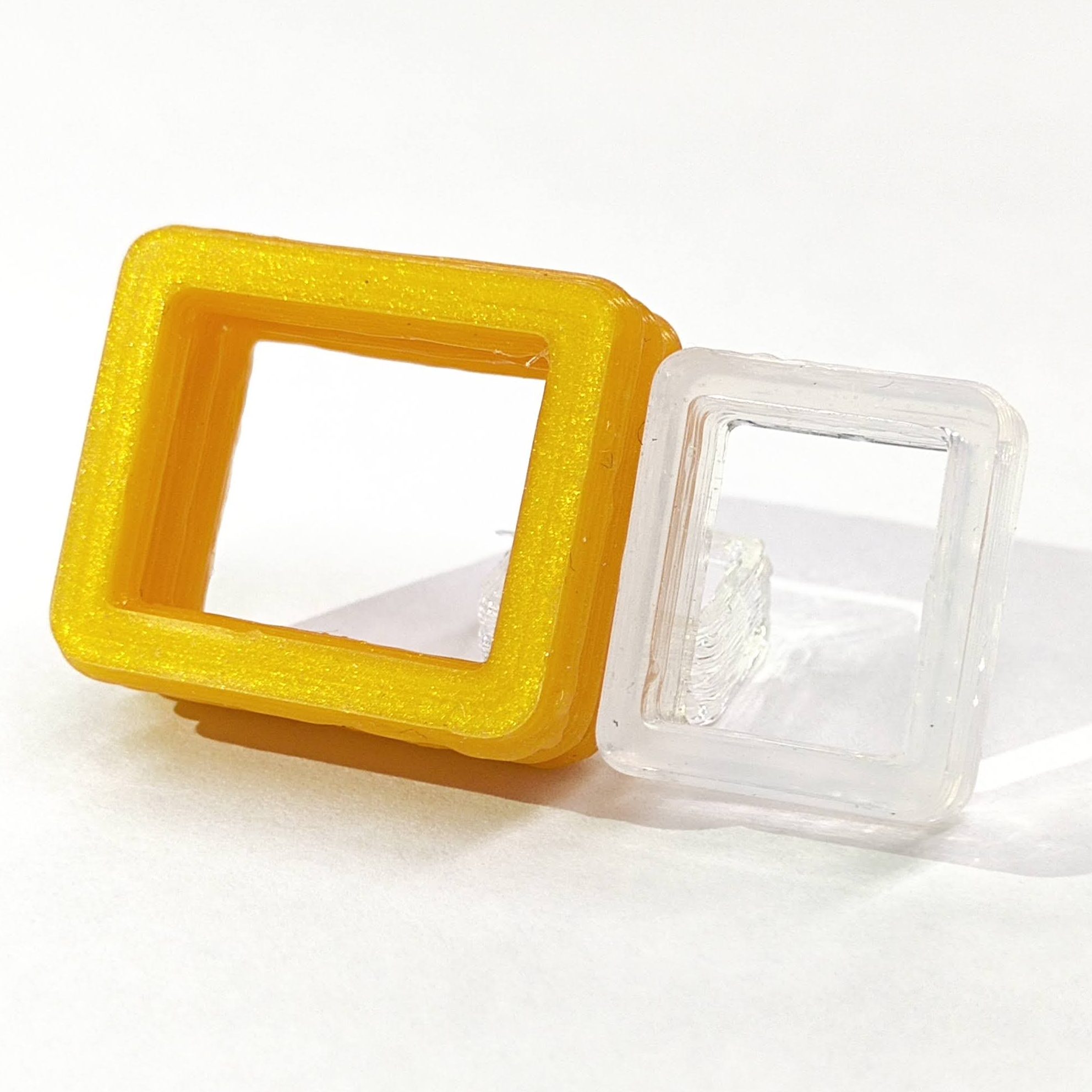

Color samples for the automotive field

For EVs, hybrid vehicles, and engine room seals like wires and connectors, custom colors and small-lot production are available.

We also consider custom colors tailored to customer needs.

<Wire Seal Shape>

<Connector Seal Shape>

<Ignition Coil Rubber Shape>

Color samples for the robotics field

Adopted for automated oyster fry transport, used as a left-right set.

Its 3D-printed hollow interior allows air injection, enabling it to curve and grip like artificial muscles, accommodating various sizes and shapes of objects.

<Robot Hand Shape (Crosslinked Joint Product)>

*Gripping an oyster fry*

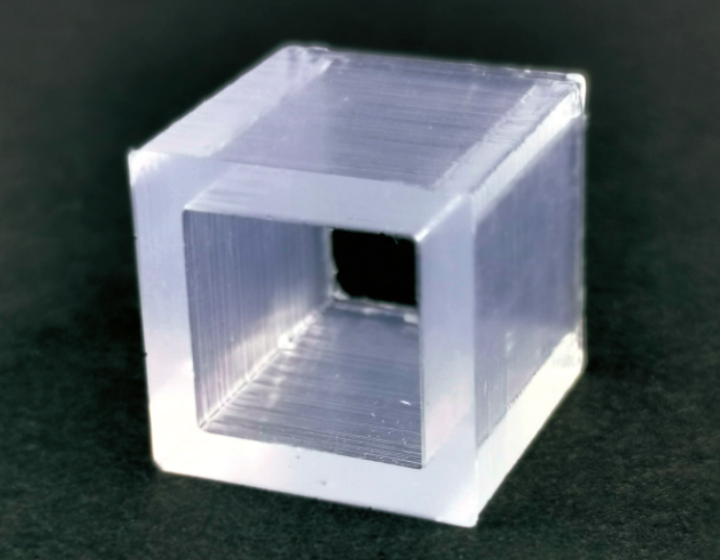

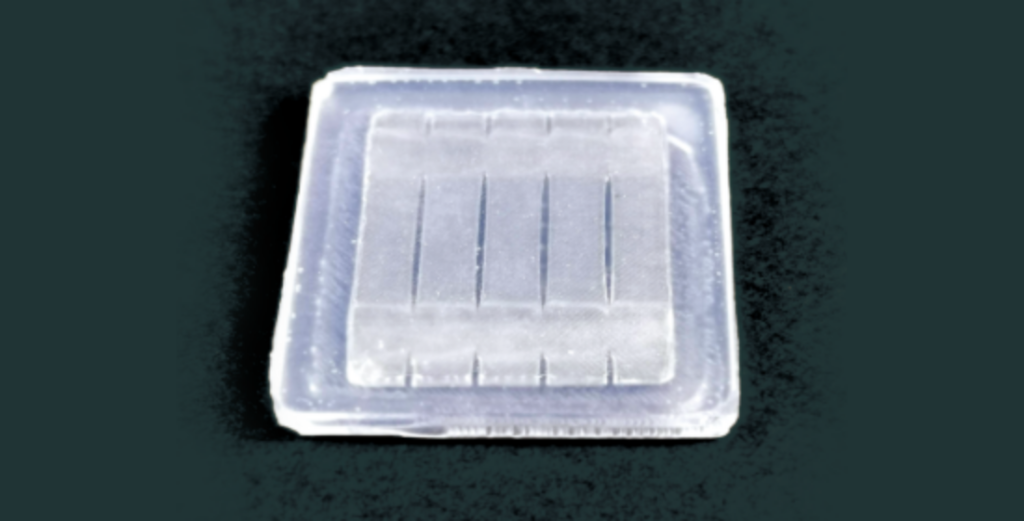

Color samples for the industrial field

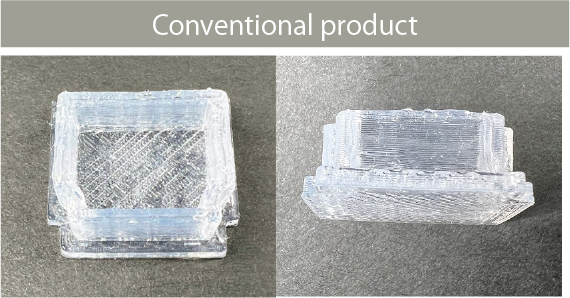

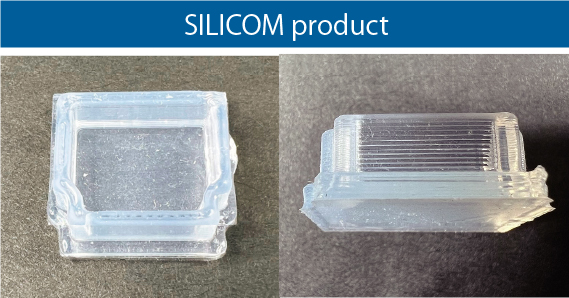

Achieves reduction of layer marks unique to 3D printing.

Reduction of layer marks unique to layered 3D printing has been achieved.

By using the uniquely developed SILICOM-specific slicer software, optimal conditions for crosslinking are set to reduce layer marks.

This enables higher-quality silicone rubber 3D printing.

Improved printability compared to conventional silicone 3D printers.

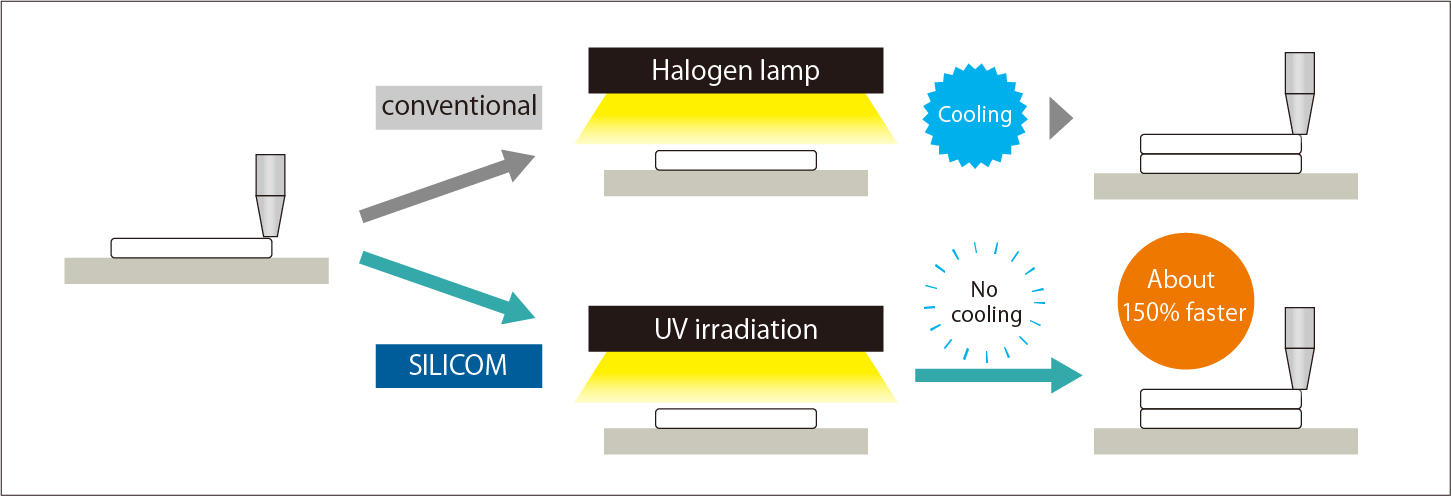

By switching from thermal crosslinking to UV crosslinking, the crosslinking time has been reduced compared to conventional silicone 3D printers.

With conventional products, layer-by-layer printing couldn’t start immediately after thermal crosslinking due to the need for device cooling. However, UV crosslinking eliminates the need for cooling, enabling immediate layer-by-layer printing after crosslinking.

Additionally, the unique slicer software significantly improves print speed and accuracy, achieving about 150% faster printing speed compared to conventional silicone 3D printers (planned, company comparison).

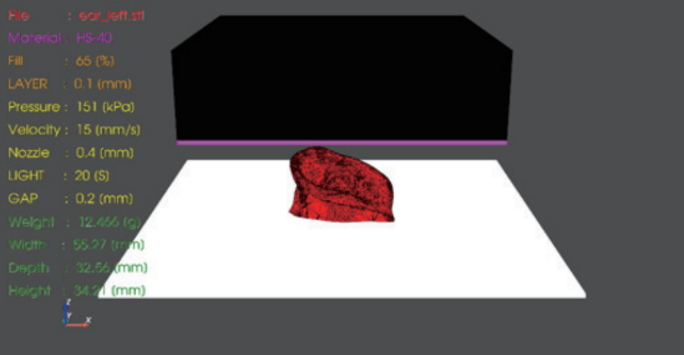

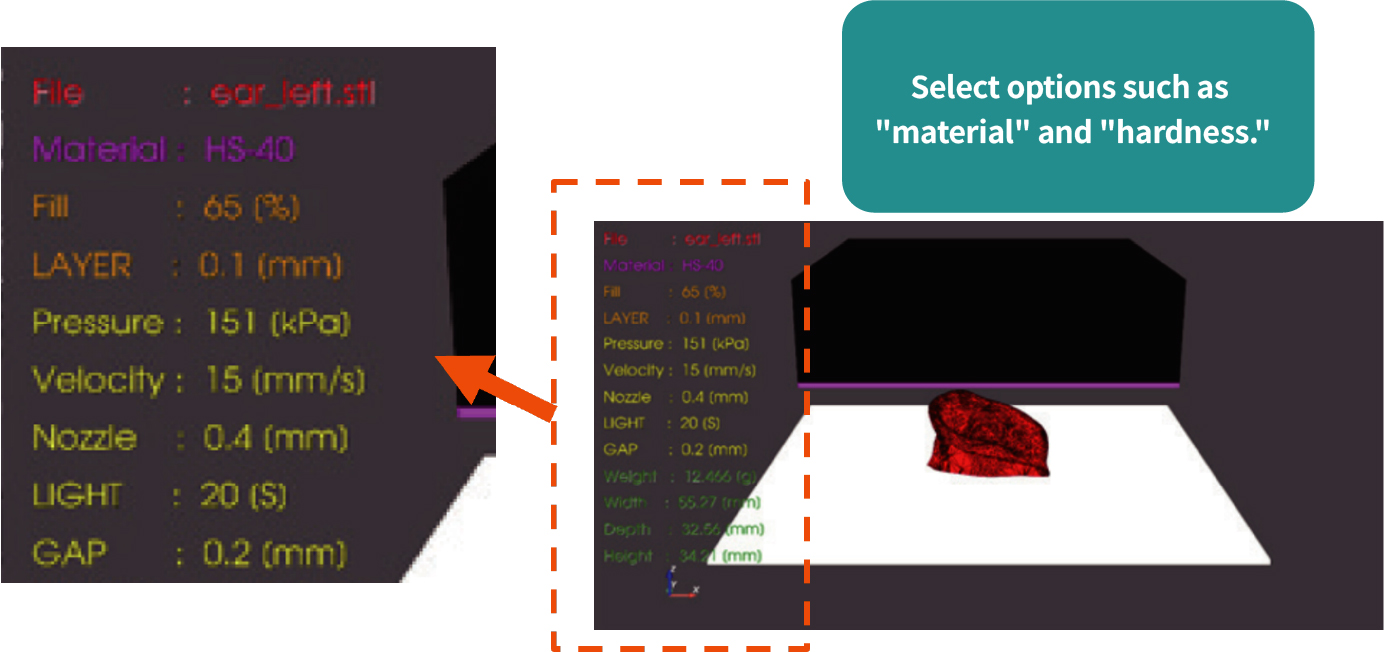

[AI-powered] Equipped with in-house developed SILICOM-specific slicer software (Patent granted)

SILICOM uses an AI-powered, in-house developed original slicer software.

The custom slicer software properly controls the liquid silicone rubber.

By utilizing learning data, it determines optimal conditions and achieves high-quality prints.

1. Easily create prints based on accumulated learning data

By utilizing the accumulated learning data, simply selecting the registered material automatically sets the optimal conditions for the print shape and material used.

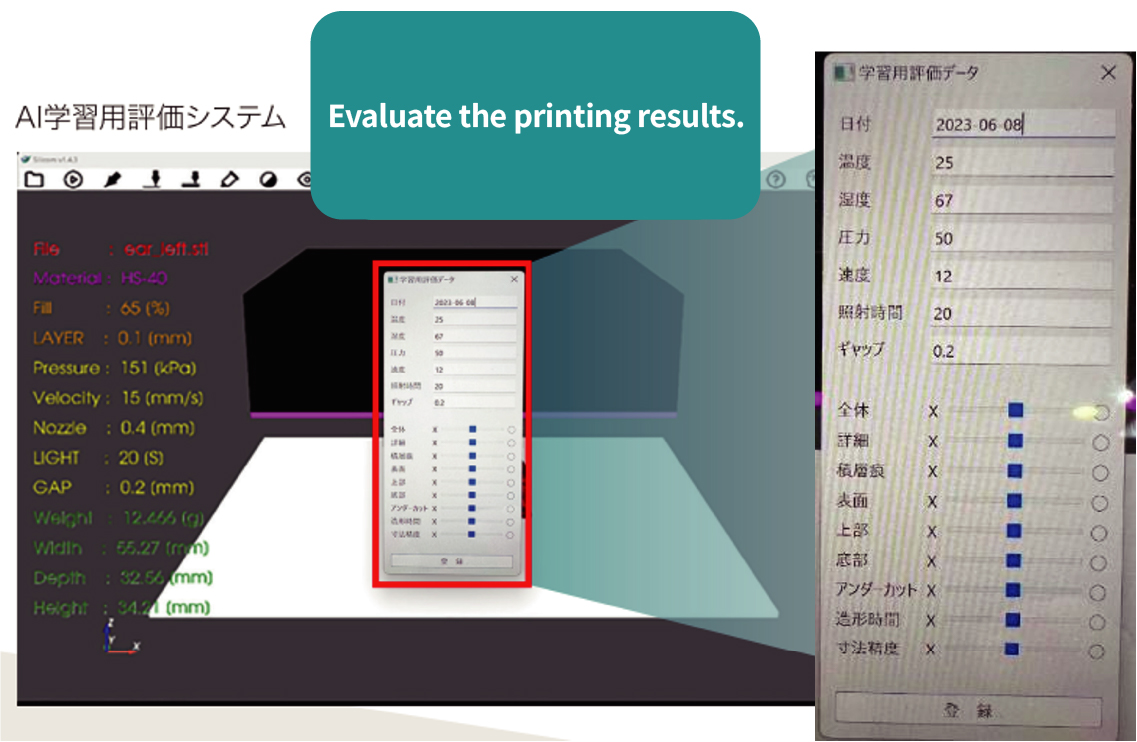

2. Equipped with AI for Improved Usability

The dedicated slicer software is equipped with AI functionality.

By using it over long periods and accumulating learning data, it automatically optimizes the objects being printed by the user.

3. Equipped with a Learning Evaluation System

By inputting the “quality” of the modeling results, the system updates the optimal printing conditions for future creations.

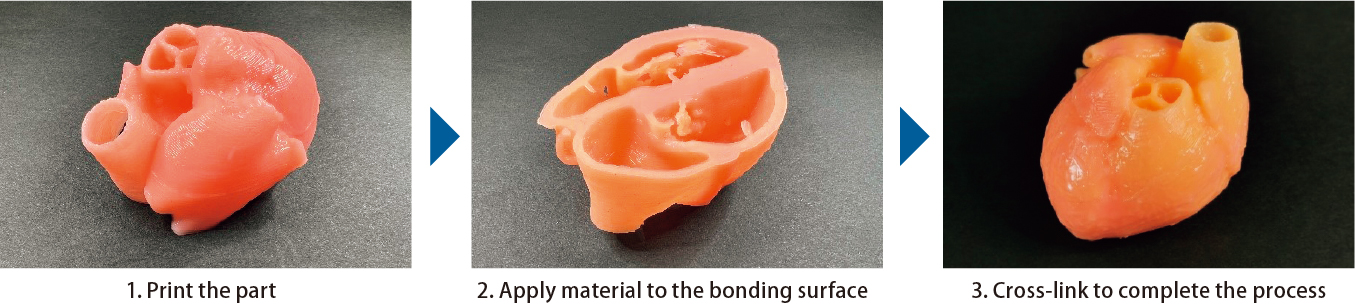

Modeling of complex shapes through cross-linking joints (patented).

By using our patented “cross-linking joint” technology, it becomes possible to create even more complex shapes.

“Cross-linking joint” is a technique that applies material used for 3D modeling to the bonding surfaces of 3D-printed parts, forming cross-links that enable complex modeling while maintaining strength.

Additionally, by bonding in the longitudinal direction, it can accommodate long modeling pieces.

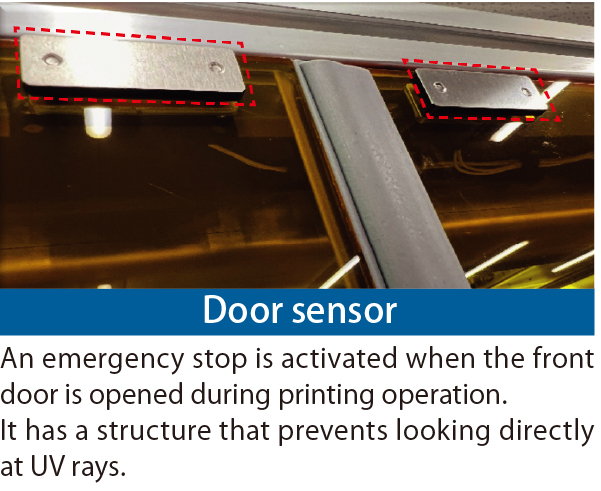

Safety design for emergencies.

To stop in an emergency, simply use the two methods below.

Additionally, the system is designed to prevent the generation of foul odors or toxic gases.

No regular maintenance or annual service fees are required.

Specification

03-3614-4100

03-3614-4100

To mail form

To mail form